Types of roof boiler rooms

The most acceptable option for placing such a boiler room is considered to be a flat roof structure. For these sources of heat supply, installations are provided: built-in and block-modular boiler room (BMK).

BMK

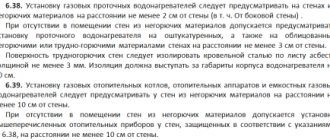

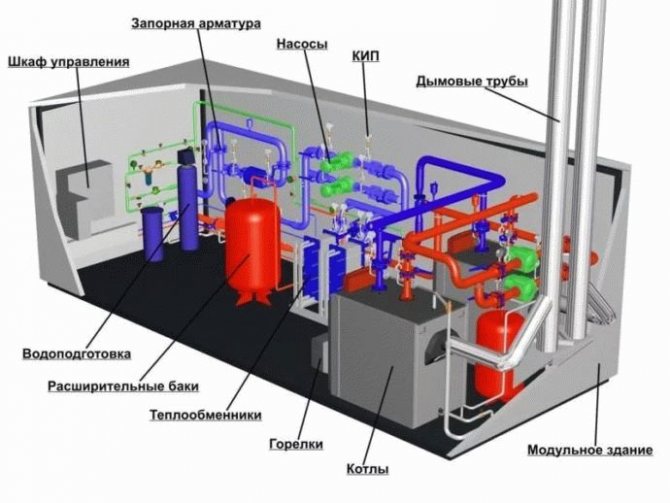

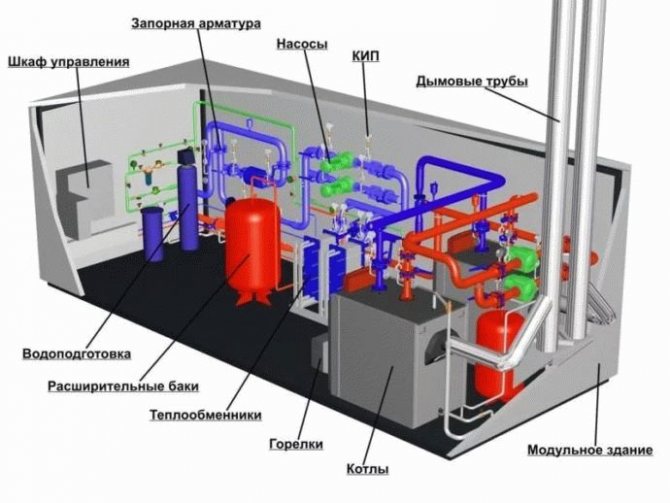

Block-modular gas-fired boiler houses are supplied in full factory complete set. They arrive to the customer essentially with 100% readiness, therefore they are launched as soon as possible. Modern roof-top boiler houses operate throughout the year in automatic mode for heating and hot water supply and do not need permanent operational personnel.

All boiler equipment is selected for the design technological parameters and complies with the current legislation in terms of ensuring safe operation. The block includes boilers taking into account the peak power, pumps for heating and hot water supply, fans and smoke exhausters, chimneys, primary devices for controlling thermal processes and an automatic control system. BMK is equipped with high-quality insulation and reliable supply and exhaust ventilation.

Built-in

The built-in roof-top boiler room in an apartment building is built according to an individual project, in which each element of the thermal circuit is carefully calculated in order to create a safe and efficiently functioning heating system.

The boiler room is most often made of prefabricated sandwich structures or standard reinforced concrete products. The assembly of the heating scheme of the boiler house is carried out on site, using precisely selected equipment, developed schemes of the built-in boiler house, in accordance with the design specifications for equipment and materials.

Completion is performed by the customer of the object or, under a separate agreement, with the installation company. The scheme of a roof-top boiler room in a built-in apartment building includes gas boilers taking into account a reserve, pumping equipment, a smoke exhaust and ventilation system, chemical water treatment and instrumentation.

Typically, such boiler houses are installed within a few days, then the process of setting up the boiler equipment and the final stage of accepting the boiler house into operation begins.

Roof boiler room in an apartment building in 2020

Roof-top boiler rooms were invented specifically so that their design could be done on the roofs of apartment buildings. It can also be installed on separate structures that are installed on special bases.

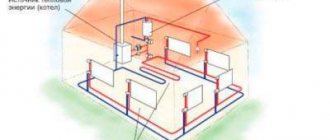

Fig. 1 Roof boiler room

Rooftop gas boilers on houses are installed in those places where designing and observing the norms of a centralized gas pipeline is, in principle, impossible. If buildings in large cities with reconstruction and point construction will be located in the city center, then the norm for the construction of elite complexes is the design of roof-top boiler houses. And all due to the fact that the area is small and, accordingly, the price rate for buying land is very high, so it is impossible to install stationary centralized heating systems.

Fig. 2 Rooftop gas boiler room

Roof-top boiler rooms can be installed both in the reconstruction of apartment buildings and in the design of new tall buildings.

Building design is possible in two ways:

- The first option is the so-called frame structure, which is located in blocks. For this option it is necessary to build a special building.Designing rooftop units in this form is suitable for multi-apartment new buildings.

- The second design option for boiler houses is rooftop gas boiler houses with block modules. Sandwich panels are used for their design and construction.

- Roof-top boilers have 2 types of boiler applications: steam boilers and hot water equipment.

Fig. 3 Gas equipment on the roof

Roof-top boiler houses for apartment buildings are a modern solution to the problem for the design of autonomous heating without connecting to a centralized gas main. After all, modern building construction sometimes requires such norms that cannot be implemented. Heat loss, thanks to this design of heating for apartment buildings, has a low rate, so the installation of a roof-top boiler room is even the norm for an economical option.

The popularity of rooftop gas boiler houses is growing every day, since thanks to such a heating design, the costs of land acquisition will disappear, there is no need to design a heating main. And even the temperature can be set more accurately.

What other advantages does the design of roof-top boiler rooms have? Are there any downsides to using it for apartment buildings? Are there safety standards that need to be followed when designing rooftop boiler rooms?

The requirements and norms regarding the design and installation of this structure are not at all significant, but nevertheless, they are. Since safety is the main thing in our world, and first of all, you need to take care of it.

Fig. 4 Autonomous boiler rooms

So what norms, precautions and maintenance should be taken in order for the roof boiler room to work for a long time and well?

- It is necessary to check the supply and exhaust valves, since thanks to them the boiler room is ventilated.

- It is necessary to install sensors, the design of which controls the operation of the gas device and which are triggered directly during the lightest fires. These are necessary so that there is no fire or explosion. It is desirable that when designing roof installations, a function is installed that automatically extinguishes the first signs of a fire.

- It is also necessary to install a gas insulating flange that can shut off the entire system at the first sign of fire.

- On the roofs of multi-storey buildings, it is imperative to install an alarm that shows and transmits light and sound signals in case of fire.

- The height of the chimney should be much higher than the height of the roof boiler room. The minimum difference is 2 m. Each gas boiler in the house must have a separate chimney, but it is imperative that they are of the same height. What will be the distance between them - it does not matter.

- Rooftop gas units must operate on separate electricity, that is, have a separate branch of the electricity network. The voltage in the house can be different, so you should not risk with electricity, since due to a power failure in the house, problems may appear in the operation of the entire heating system. A diesel generator can be used as an independent power source.

- It is impossible to install this equipment directly above apartments in houses. The presence of a technical floor is a prerequisite for the installation of a roof boiler room. The floor on which the rooftop gas units will stand must be made of reinforced concrete slabs.

- Do not forget that this heating equipment makes a lot of noise, therefore, in order to be able to install roof-top boiler rooms in multi-storey buildings, special requirements are required in accordance with the norms of sound insulation in the premises.

- The boiler room should have windows and doors that lead directly to the roof.A separate lift is mandatory as it will only be used by firefighters. It is also necessary to design the service exit. The boiler room must be lit according to the standards (0.03 sq. M / 1 m³).

- You shouldn't forget about the service personnel either - there should be a separate safe exit for them when designing.

Fig. 5 Gas equipment on the roof

After the design and installation of the gas roof boiler room, it is necessary to look after it, that is, to do service. The service personnel can also handle this. But you also shouldn't forget about the representatives of the gas service. They should be sure to check this equipment once a year at least.

When considering all the disadvantages and advantages of this unit, you can see that there are, of course, more advantages. Construction companies choose rooftop units for their installation in apartment buildings. And all due to the fact that it is both economical and reasonable, and they work in accordance with all established standards. This is especially convenient when either there is no centralized gas pipeline, or it is abandoned during construction.

And so, the main advantages of this equipment:

- Rooftop units can do without a separate place for themselves. That is, it is not necessary for them to install an additional building. A roof is also suitable for the operation of gas equipment in a multi-storey building. The frame or water collector can be located far from the design of the roof boiler room (attic, basement).

- Heat loss is very low during the operation of these units. There is no more need to install heating mains, and thanks to this, much less money will be spent on equipment maintenance.

- The costs of connecting to centralized communications are also reduced. And everyone knows that for this you need to give a tidy sum in our time.

- The design of roof-top boiler houses is no more demanding. Forced ventilation and arrangement of chimneys is not required. SNiP makes it possible for such a huge equipment to heat buildings up to 30 m high.

- When designing these equipment in apartment buildings, all standards will be observed and, according to SNiP, the system can be fully automated. The operator will be hired not even for a whole working day, but only for a couple of hours. Thanks to SNiP, the norms for the design of roof-top boiler rooms will make it possible to install sensors on them that will monitor the temperature outside and themselves turn on the required level of heating.

- It is also good that people will no longer have to adjust to the norms established in the country (there is no heating in summer). The unit, if necessary, can work in the summer. Who can service the rooftop boiler room? Yes, simple staff who look after her all year round. You won't even need to call specialists. This equipment is easy to operate.

It is interesting: Fines for non-posting of information in the GIS Housing and Utilities in 2020

If the equipment is designed according to SNiP, then in no case should it heat additional buildings. Since SNiP states that the power of the equipment should be exactly as much as is needed for the design and heating of the whole building.

Fig. 6 Based on two boilers

The pros and cons of the roof boiler room are already clear. Now it's worth talking a little about the cons. Disadvantages according to SNiP and design standards are associated with the requirements that were in the design of the building itself, where the equipment will be installed.

- Introduction of new standards in the construction of lifting systems, as well as design according to SNiP and installation of a heating system.

- If the weight of the equipment in the documents is limited, then the roof boiler room cannot exceed the weight specified in the SNiP. And, accordingly, the installation will fail.

- Complex automatic systems must be installed for this equipment. This is also said in SNiP.

- It is necessary to comply with all norms after designing work with such gas equipment.

- And it will not be superfluous to install fire-safe systems in roof boiler rooms, which are made according to all standards and are described in SNiP.

When designing, building codes and SNIP warn that the capacity of roof-top boilers on houses should be exactly that which can heat one building. Snip also says that it is forbidden for equipment to exceed the power required for the consumption of a multi-storey building. All standards are specified during design. The calculation and norms for Snip should be carried out based on the maximum value of the coolant flow rate.

If it is necessary to use the heating element of the roof boiler room on the roof of the house in order to heat adjacent ones, then only in this case it is possible not to adhere to the norms and SNIP, but to slightly increase the performance of the unit. The maximum that can be is 100% of all electricity in the main building.

Fig. 7 Block-modular boiler rooms

If suddenly in the future it is planned to design according to all heating standards for adjacent buildings, then a roof boiler room, which is called a block-modular one, for a multi-storey building is simply the best option for design. The block-modular system can be rebuilt to suit any needs.

Installing rooftop boilers on houses is a very successful business that is becoming more and more popular. The design of this equipment is a fairly profitable solution. Although such units on houses appeared on the territory of the Russian Federation and other CIS countries relatively recently, they have already managed to gain a good reputation. Due to the fact that the equipment is located on the roof of the house, there is a smoother heating of the apartments.

January, and with it winter, exceeded half. But houses in our climate have to be heated both in spring and autumn, and hot water is generally needed all year round. And I would like to receive heat and hot water with minimal costs. Desirable - reducing to zero losses on heating mains. We talked about individual boilers in the article "How to avoid problems with the installation of autonomous heating in an apartment?" Now we will discuss the advantages and disadvantages of another option for the reconstruction of the heating system - roof-top boiler houses.

A roof-top boiler room is an autonomous heating source intended for heating and providing hot water supply to residential buildings. As the name suggests, it is erected on the roof of a building, in a specially equipped room. We will not consider stationary roof boiler rooms here. They are constructed during the construction phase of the building, are linked with it in design and infrastructure, so local and regional authorities do not have any questions about them. However, it is possible to recommend building stationary roof-top boiler houses when there is a shortage of thermal power in the microdistrict being built up.

But block-modular roof boiler rooms are purchased for an already finished building. The block-modular boiler room is manufactured according to the required parameters, assembled by the supplier company, transported to the place of installation and commissioning in a ready-made form, provided with a proprietary guarantee. Its connection to heating networks takes an extremely short time. Another very interesting and useful property of modular roof-top boiler houses: their heating point can be located not only in the boiler room itself, but also in the basement of the consumer building, on the basement or on the first floor.

The heat point consists of elements of thermal power plants that ensure the connection of these installations to the heating network, their operability, control of heat consumption modes, conversion, regulation of the heat carrier parameters and the distribution of the heat carrier by types of consumers.It transfers hot water to heating systems, to the hot water supply system. It also supplies heat to the ventilation system of a residential building (without which, say, elementary garbage chutes would turn into a source of an extremely unpleasant odor, and icy winds would whistle along the risers in the bathrooms).

But why is it so important that in the case of a block-modular boiler room, it can be placed in the basement of the consumer building, as well as on the basement or on the first floors? Yes, because it makes it possible to link the modular roof boiler room with the heating, hot water supply and ventilation systems available in the house. Risers, wiring, heating devices - all this will remain in place. Noisy pumps will also remain in the basement or plinth, driving water upward. At the same time, the block-modular roof boiler house operating on gas is in fact a huge individual heating boiler, this gives us the opportunity to formulate its advantages.

First of all, it excludes losses on the heating main, which will reduce the current costs of heating due to resource savings; eliminates the risk of being left without heat and hot water in the event of a break in communications. In the event that the capacity of centralized boiler houses in the microdistrict is not enough to ensure the proper parameters of the coolant in frosts, it will provide the house with heat in any conditions. These are its advantages in common with individual heating boilers.

The second group of advantages distinguishes it for the better from individual boilers. Well, the most important thing is the ability to preserve the very layout that was originally laid down by the builders of the house. After hanging a heating boiler in the kitchen or in the hallway, we will be forced to lead pipes to it from batteries located throughout the apartment (earlier, batteries were powered from vertical risers, and horizontal connections to them ran through attics, basements). So the house is switching to individual boilers - each apartment will inevitably undergo significant repairs, which may not be at all in the plans and financial capabilities of the residents). And in the case of a roof boiler room, these unpleasant troubles can be avoided.

It's interesting: Video surveillance at the entrance: law and installation rules 2020

The third group of merits is associated with exploitation. Unlike the gas water heater, which worked in a short-term mode, the individual heating boiler during the heating period, seven months in our latitudes, burns constantly. It is, of course, automated. But it's still good if a large family lives in the apartment and someone makes sure that the younger ones do not get to the boiler with a set of screwdrivers.

On the other hand, the flexibility of an individual heating boiler is, of course, higher than in the case of a centralized modular roof boiler room. You can run it in heating mode and just on a too cool and wet summer day - in the case of a roof-top boiler room, you will need a decision from the house council or a similar body.

Economics will give you the answer to this question. First of all, it must be borne in mind that the transition of a house to individual boilers and the installation of roof-top boiler houses, although it increases the comfort of living, and gives in the long term savings on heating and hot water bills, but is associated with the need for capital investments. If the residents of the house who want to improve the situation with the heat supply do not have free funds, then it is better to forget about this option and restrict ourselves to standard heat conservation measures.

These are not the only costs. The rooftop boiler room cannot be mounted on floor slabs, under which the living space is located - that is, in the absence of a technical floor, it will have to be erected on a part of the roof. Under the roof boiler room there must be waterproofing with a layer thickness of at least 100 mm, and reliable drainage systems. With a building height above 26.5 m (above the standard nine-story building), additional approvals from the fire services will be required.But the guidelines can be given something like this.

For houses with 36 apartments and less, it will most likely be cheaper to install individual heating boilers during reconstruction. But with a hundred apartments and more, the economy will lean very strongly towards the roof boiler house (the effect of capacity growth is faster than the price!). In intermediate cases, calculations of various options are necessary - this is a responsible and qualified work of estimates in the construction industry, but we tried to give the most general guidelines and the most general ideas about roof-top boiler houses.

If you liked the article, recommend it to your friends, acquaintances or colleagues related to municipal or public service. It seems to us that it will be both useful and pleasant for them. When reprinting materials, a reference to the source is required.

offers design and installation of boiler rooms on the roof of a multi-storey building!

Our company offers the best value for money. We work on a turnkey basis, we provide a full cycle of services from project preparation to commissioning using the most modern energy-saving technologies.

The efficiency of roof-top boiler houses in an apartment building from Alyansteplo is 94–95%, they pay off in several years. Fill out the questionnaire, call, ask - we will advise you on all questions.

Operation and maintenance of the boiler room on the roof of the house is possible either in a block-modular design, or if its construction was envisaged even at the stage of building the house: this model is called “built-in”. But in 95% of cases, the roof boiler room of a residential building is a complex of block-modules that are assembled at a factory, brought to a high-rise building and assembled on site.

The construction of a boiler room on the roof of the house is ordered to save money and get rid of the "binding" to centralized heating networks. A private boiler room gives residents of the house from 30% savings on payments, and also the opportunity to start and end the heating season, relying not on the schedule, but on the real air temperature.

Prices for a boiler room on the roof of a multi-storey building start at 5 million rubles. This includes all work, including design, construction and commissioning, and the full cost of the equipment.

Installation of a boiler room on the roof of the house - obtaining a completely autonomous heating plant. This has several advantages:

- There is no need to conclude contracts with all kinds of organizations and pay them for the maintenance of the boiler room on the roof of the house.

- Reduction of heat losses, which invariably exist if the boiler room is installed at a distance from the heated object. The heating networks, through which the carrier is transferred to the dwelling, have been updated, which means that their efficiency is higher.

- The payment for heat supply is reduced to a minimum level, including because the rooftop gas boiler house in an apartment building is automated and does not require the constant presence of service personnel.

- You can start and end the heating season when it is convenient for residents and dictated by common sense. If the cold weather came earlier, the roof-top boiler room can be started earlier than the “official” date.

- Many people ask if houses with a rooftop boiler are safe. Our answer is absolutely. All installations undergo repeated testing, complex signaling and fire-fighting equipment is installed. If you turn to professionals for the construction of a boiler room on the roof of a multi-storey building, any risks are reduced to zero.

Question number 1: Is the gas boiler room on the roof of a multi-storey building a common property?

Answer: Yes, in accordance with Art. 36 p. 1 of the LC RF. All technical premises belong to the residents of the building. Responsibility for the boiler room rests with the contractor who has been entrusted with this task by the homeowners. That is why, if the contract for the maintenance of the boiler room on the roof of the house was concluded without the consent of absolutely all residents of the house, it can be challenged in court.

Question number 2: Is the roof boiler room a separate floor?

Answer: No, the roof boiler room is a building that is being built on the roof and is not considered an additional floor. A technical room is considered a floor only if it is located in the attic, in the basement or somewhere between residential floors, while it must be higher than 1.8 m in height.

Question number 3: Do I need a license to maintain a boiler room on the roof of a multi-storey building?

Answer: A license is compulsory for boiler houses that operate on natural gas and serve the population, and at the same time have a hazard class higher than 4. All this is specified in Federal Law 116. The license is also needed for boiler houses that are located on the technical floors of a residential building.

Question number 4: Is there any noise from the boiler room on the roof?

Answer: Not higher than 60 dBA in the boiler room itself and 35 dBA in nearby apartments - these are the restrictions dictated by the legislation. Noise should not disturb the occupants. The most you will hear is a minor hum on the upper floors.

Question number 5: Is the roof boiler room profitable for residents?

Answer: The cost of the boiler room on the roof of a multi-storey building is divided among all tenants, if they are the owners. The service life is over 15 years, after which it is necessary to buy a new boiler. At the same time, residents pay exclusively for electricity and gas, saving on heating by an average of 30–45%.

It's interesting: UDS - what is it in housing and communal services decoding of abbreviation 2020

offers design, construction, commissioning of a boiler room on the roof of the house, as well as its maintenance. Fill out the questionnaire, and we will calculate the price of the boiler room on the roof of the house, and by phone you can get detailed advice on all issues and controversial issues.

An important factor when choosing an apartment in a multi-storey building is the ability to save on heating and hot water supply (DHW). It is believed that the use of an individual boiler plant significantly reduces utility costs. In this article, we will consider why developers are building autonomous adjoining boiler houses, what this heating system is, and also how profitable and safe it is for residents.

Today in Russia, the vast majority of residential buildings, hospitals, kindergartens and office buildings use a centralized heating system and hot water supply from district heating plants (RTS), combined heat and power plants (CHP) or large boiler houses.

It's no secret that the state of both the CHPPs themselves and municipal boiler houses and heating networks leaves much to be desired, and in some cities it is close to catastrophic. Deterioration of heating mains, irrational use of capacities, high energy consumption of obsolete equipment, frequent accidents and repairs lead to the fact that consumers are forced to pay huge heat losses (up to 20% of consumption), depreciation of networks and labor costs for maintenance personnel.

In addition, residents of houses connected to the central heating system depend on the start and end of the heating season adopted by the city administration, regardless of the room temperature. This fact forces them to use household heaters in the fall, which leads to an increase in electricity bills, and to shut off the batteries in the spring, continuing to pay extortionate receipts for heating.

Preventive shutdown of hot water in the summer for a period of two weeks or more is also associated with a large number of objects connected to one CHP or boiler house, where diagnostic or repair work is being carried out.

Often, in apartments on the upper floors, the quality of heating and hot water decreases due to insufficiently high temperature of the water in the pipes.

These disadvantages have led to the fact that developers are increasingly building block (modular) boiler houses for heating housing complexes and even individual apartment buildings.

- Lack of engineering infrastructure on the construction site;

- The remoteness of the facility from city heating plants, but the presence of a gas pipeline nearby;

- Capacity shortages and inefficiency of the district heating system;

- Complexity and / or high cost of approval of technological connection to existing networks;

- The density of buildings in the central regions interferes with the work on the laying of heating networks;

- The building area, free of heating mains, allows you to equip attractive recreation areas, parking spaces, playgrounds.

In addition, the presence of an individual boiler room is presented by developers as an additional advantage for potential clients and allows the facility to be positioned as a comfort-class housing.

Block boiler plants (BKU) are manufactured at the plant and delivered to the site already assembled, the so-called block modules. Outside, it is a small one-story building, similar to a sandwich panel trailer, inside which the following components and systems are installed:

- hot water boiler, fuel combustion chamber, heat exchangers;

- pumps for circulating water in the system;

- equipment for water treatment and water purification;

- gas ducts, chimneys;

- gas equipment (when using gas);

- DHW circuit equipment (if any);

- automatic control and dispatching system, instrumentation.

By type of fuel consumed distinguish gas, solid and liquid fuel BKU. Combinations of several types of fuel are possible. Gas boiler houses are most widespread due to their high efficiency (up to 95%), they are also the most environmentally friendly. Solid fuel is coal, firewood, peat, pallets, liquid fuel - fuel oil, diesel fuel, waste oil

By type of execution the following modules of boiler plants are distinguished:

- Freestanding used, as a rule, for heating several buildings and located at a certain distance from them.

- Attached placed close to the end of the structure.

- Rooftop located on the roof or technical floor of an apartment building.

The latter version is gaining popularity due to its technical and economic advantages, as well as better safety and environmental performance.

Savings on utilities compared to apartments of a similar area, heated from the backbone networks, is at least 45%, and in some cases reaches 200 - 300%. This effect is the sum of several factors: there is no need to pay for heat loss, the cost of transporting the coolant, the cost of maintaining and repairing worn-out trunk networks, labor of workers.

Calculation of payments for heating and hot water becomes clear and understandable for the consumer. It consists of the physical volumes of resources actually consumed for heat production for the billing period, multiplied by the tariffs corresponding to each resource. The consumption of raw materials, namely gas (or other fuel), cold water and electricity, is confirmed by metering devices. The total cost is distributed among the owners in proportion to the area of apartments and non-residential premises.

An additional advantage of having a house boiler house will be the independence of residents from the schedule of the heating season and the planned outages of hot water adopted by the city authorities. The ability to independently promptly control the power of heat generation, depending on the temperature outside the window, allows efficient use of resources, saving on utility bills.

In terms of safety, modern autonomous boiler plants are not inferior to centralized systems.From design to commissioning, the process of creating a modular boiler house is controlled by supervisory authorities. In addition, automatic safety systems built into the control loop signal threats and block the operation of equipment in emergency situations. In case of breakdown, a backup boiler and pumps are provided.

In terms of the environmental parameters of exhaust gas emissions into the atmosphere, a modular boiler house is much safer than a CHP plant, since the volume of pollution is an order of magnitude less, and if it is located on a rooftop, its dispersion improves.

The only drawback of an autonomous boiler room for apartment owners is the fact that it belongs to internal engineering systems, that is, common property. According to the Housing Code of the Russian Federation, repair and maintenance of such property is carried out at the expense of the owners of residential and non-residential premises. In practice, these needs are included in the tariff for the maintenance and repair of common property in an apartment building. But since the planned service life of the equipment is designed for 25 years, the considerable cost of replacing and installing it is stretched over time and distributed over the area, as a result, for the owner of the apartment, it remains profitable in comparison with the centralized heating system.

»

Other

Sewerage blockage in an apartment building: who is to blame? 2020 year

Read more

Other

How to keep accounting records in a HOA - step-by-step instructions 2020

Read more

Other

How to conclude a garbage collection agreement? 2020 year

Read more

Other

How to abandon a management company: step-by-step instructions 2020

Read more

Excellent article 0

Advantages and disadvantages

The main advantage of a rooftop gas boiler house is its autonomy, as a result of which heating and hot water supply is supplied directly to the house on which it is installed. This helps to reduce heat losses, in connection with which the cost of a unit of heat energy KKg is significantly reduced to a minimum.

At the request of the customer, it is possible to conclude an agreement with the operating organization, which simultaneously serves several similar objects.

The beginning and end of the heating season begins as needed, and not by the decision of the municipal authorities. A high level of operational safety is guaranteed by modern thermal management systems.

Roof-top boiler houses have a number of negative qualities:

- Installation restrictions, such equipment can be installed in a house no higher than 9 floors.

- Increased vibration due to the operation of circulating pumps, smoke exhausters and fans.

- High price for the production of the project, the purchase of equipment and installation and construction work. Depending on the capacity and completeness, the approximate investment in such a heat supply scheme will amount to 5-18 million rubles.

House requirements

It is allowed to install such boiler rooms on the floors of buildings, except for buildings for explosion and fire hazard with categories A and B. Their placement directly on the ceiling is not allowed. The maximum permissible thermal power KKg for houses is 3.0 MW and for industrial facilities - 5.0 MW.

There are several prohibitions when installing rooftop heat sources:

- The height of the boiler room together with the object cannot exceed 26.5 m, which is equal to a 9-storey typical house.

- The dimensions of the combustion room should not be larger than the plan of the house.

- It is not allowed to increase the width of the walls, and to carry out re-equipment of the roof to reduce the load on the basic supporting structures.

Installation of heating equipment is carried out only after the project has been appraised.

Normative requirements of SNiP for design

Regardless of the choice of the type of boiler room design, the developers of its project must rely on the requirements of SNiP.For this, a whole section of rules II-35-76 is provided, which applies to general standards for the design of boiler rooms, as well as addition P 1-03, dedicated specifically to roof structures. The technical solution must, in particular, comply with the following rules:

- Walls and engineering structures should not directly interface with the walls of residential premises.

- In multi-storey buildings, the construction of roof boiler rooms should not be carried out on the floors of residential premises.

- The control system should provide for autonomous signaling.

- The height of the chimneys is at least 50 cm relative to the highest point of the building.

Also, without fail, the technical rooms set aside for boiler rooms must initially have ventilation. This already applies to fire safety measures when it comes to the operation of gas equipment.

Roof requirements for installation

When building this type of boiler room, it is necessary to provide for an exit directly to the roof. The exit to the boiler room from the entrance of the house must be carried out along a marching staircase. With a slope angle of more than 10% on the roof of the house, they equip bridges of 1 m in size, with a railing height of at least 0.9 m.

The constructions of ladders and handrails should be foreseen from fire-resistant building materials. The total load of the boiler equipment should not exceed the calculation of the loads on the roof.

The position of the boiler building should be built taking into account wind loads in the climatic zone of placement and taking into account the specific stresses laid down in the design of the house.

Design standards for gas-fired roof boilers

The design of KKg is carried out by companies licensed for the corresponding type of work. Prior to approval, the project must be coordinated by the architectural supervision, the SES, the fire inspection with the operating organizations, which formalized the technical specifications in the design process.

Since the design services of boiler houses are quite expensive, it is recommended to pay for the work performed after the project has been agreed with all regulatory authorities and approved. This will become possible only if the design documentation meets the requirements of SNIP, VSN and the rules for the operation of boiler equipment.

The KKg floor is made with waterproofing, capable of providing a flood of water up to 100 mm high. Window openings must provide natural illumination, and therefore they are installed from a ratio of at least 0.05 m2 per 1 m3 of the total volume of the heat supply facility.

The piping scheme for in-house heating and ventilation networks is carried out according to a dependent scheme, through a mixing unit for supplying heat energy, and the hot water supply system - in a closed circuit through a heat exchanger.

Heating systems are divided in front, with an individual unit for commercial metering of heat energy. A chemical water treatment system must be installed in the boiler room to supply soft water to the boiler and the heating circuit. These requirements are met in order to prevent scale formation on heating surfaces.

What boilers to use

As sources of thermal energy in KKg, automated hot water boilers are used, capable of heating water with a coolant to 95 C and a pressure of up to 1.0 MPa.

For example, modular boiler room ARGUS TM-1000.00.PR.10 with a capacity of 1050 kW, equipped with:

- Gas boiler PROTHERM 120 SOO with a capacity of 105 kW and an efficiency of -90%, 10 units.

- Pump group with centrifugal pump WILO HWJ 202 EM 20L.

- Expansion diaphragm tank REFLEX N 200/6.

- Automation and regulation system.

- A group of instrumentation and primary sensors.

- Chemical water treatment unit.

- Smoke ventilation system.

How to supply gas

The gas pressure in the gas pipeline for KKg should not exceed 5 kPa.

The external wiring of the gas pipeline to the boilers is carried out in places that are convenient for performing subsequent maintenance and exclude the possibility of its rupture. Connection of other consumers to this gas pipeline is not allowed.

The gas pipeline should not pass through ventilation systems, windows and doors. The internal gas pipeline in the boiler room is laid openly, while there should be free access for control and technical inspection of safety and automation devices.

Shut-off and control devices on the gas pipeline are installed at the inlet to the boiler room, on each branch to the boiler unit, in front of the ignition devices, on the purge gas pipelines and drainage fittings.

In addition, a safety shut-off valve (SSV) with an electromagnetic actuator is installed on the gas line in the safety system, which cuts off the gas in an emergency.

Roof power supply

Electrical equipment KKg must comply with the PUE, as an object of the second category of electrical supply reliability.

The building should be provided with lightning protection and a gas pipeline grounding system. The illumination of the premises must comply with the requirements of SNiP 23-05-95. Electrical equipment must have automatic protection against overheating and overloads in the network.

The power supply scheme should provide for the possibility of switching on backup electrical equipment when the main device exits, for example, a pump, a fan and a smoke exhauster.

Safety automation should ensure that the gas supply to the boiler is turned off in case of an emergency: high gas pressure, separation of the torch from the burner, gas contamination in the boiler room, low draft in the furnace, high temperature and pressure of the coolant.

Fire safety

There are a number of important security fire requirements for KKg in a multi-storey building:

- The location of the boiler room directly above the apartments is prohibited.

- The boiler facility is assigned a category of class "G" for explosion and fire hazard.

- The height of the ceilings of the object must be higher than 2.65 m

- Door width over 0.8 m.

- Fireproof partitions must be installed in the building.

- The room must have a separate emergency exit.

- The facility is equipped with fire-prevention sound and light alarms and emergency fire-extinguishing systems.

Questions, answers and reviews about boiler rooms on the roof of a multi-storey building

Question number 1: Is the gas boiler room on the roof of a multi-storey building a common property?

Answer: Yes, in accordance with Art. 36 p. 1 of the LC RF. All technical premises belong to the residents of the building. Responsibility for the boiler room rests with the contractor who has been entrusted with this task by the homeowners. That is why, if the contract for the maintenance of the boiler room on the roof of the house was concluded without the consent of absolutely all residents of the house, it can be challenged in court.

Question number 2: Is the roof boiler room a separate floor?

Answer: No, the roof boiler room is a building that is being built on the roof and is not considered an additional floor. A technical room is considered a floor only if it is located in the attic, in the basement or somewhere between residential floors, while it must be higher than 1.8 m in height.

Question number 3: Do I need a license to maintain a boiler room on the roof of a multi-storey building?

Answer: A license is compulsory for boiler houses that operate on natural gas and serve the population, and at the same time have a hazard class higher than 4. All this is specified in Federal Law 116. The license is also needed for boiler houses that are located on the technical floors of a residential building.

Question number 4: Is there any noise from the boiler room on the roof?

Answer: Not higher than 60 dBA in the boiler room itself and 35 dBA in nearby apartments - these are the restrictions dictated by the legislation. Noise should not disturb the occupants. The most you will hear is a minor hum on the upper floors.

Question number 5: Is the roof boiler room profitable for residents?

Answer: The cost of the boiler room on the roof of a multi-storey building is divided among all tenants, if they are the owners. The service life is over 15 years, after which it is necessary to buy a new boiler. At the same time, residents pay exclusively for electricity and gas, saving on heating by an average of 30–45%.

offers design, construction, commissioning of a boiler room on the roof of the house, as well as its maintenance.Fill out the questionnaire, and we will calculate the price of the boiler room on the roof of the house, and by phone you can get detailed advice on all issues and controversial issues.

To calculate the cost of the boiler room, please fill out the questionnaire for the boiler room. The questionnaire can be completed online or downloaded. For any questions you may have: multichannel telephone e-mail

Fill out the questionnaire online

Calculate the cost of the boiler room

You may also be interested in

Why you need a fuel storage A fuel storage is a container where fuel is stored, usually for diesel boilers and power plants. It is simply dangerous to use the pipeline in this case due to the impossibility of isolating it in the event of an emergency. Fuel storage facilities are also used at filling stations.

Types of boiler houses by type of location in production Choosing a boiler house is a responsible task that requires solving a number of important issues. What is planned to be heated? What is the best fuel to use? Which boiler to take - steam, hot water or mixed? And finally: where to locate the future boiler room?

How to select burners for boiler rooms? Modern automatic burners are needed in different situations - not only when building a new boiler house, but also when reconstructing or modifying an old one, as well as when equipping a "manual" boiler house with automation and control systems. They are equally used in hot water and steam units.

Dismantling the boiler room The need to dismantle the boiler room may arise not only because of the emergency or liquidation of the enterprise that served the boiler room, but also in order to modernize the existing equipment, or during the conversion work.

Boiler room cleaning Timely boiler room cleaning is one of the prerequisites for its normal functioning. First of all, boiler plants, radiators and heat exchangers themselves require cleaning; in other words, those systems through which a coolant (water or steam) is constantly circulating, which is the cause of scale, rust and deposits.

Boiler room commissioning

The procedure for receiving the roof boiler room is determined by the PTE. The main stages of commissioning KKg:

- Project development.

- Approval of the completed project and its coordination with the municipal profile departments - architecture and housing and communal services.

- Performing technical expertise.

- Purchase of equipment and materials according to the section specifications and materials.

- Manufacturing of a boiler room and its installation on the roof of the building.

- Commissioning of boiler equipment.

- Creation of a commission for acceptance of the boiler house into operation. The commission should include representatives of the customer, the design and installation organization, the city gas company, as well as municipal departments for capital construction, housing and communal services, SES and fire inspection.

- After the signing of the act by all members of the commission, they issue a permit for operation in the gas supply organization.

Who pays for the installation of the boiler room

Roof boiler room of a residential building - this is the property of the residents of the house, installation and maintenance is part of their obligations. The installation, erected as part of the overhaul, is sponsored by the residents of the house, the funds are taken from contributions to the overhaul fund. If there is not enough money in the fund for the installation of the boiler room, the tenants decide to collect the required amount.

What is included in the total cost: project of a roof boiler room for a residential building, production of the system, its delivery and installation. The budget is laid not only for adjustment, installation, ensuring the safe operation of the system, but also for insurance. You can order a turnkey work, including pre-design study and until the system is put into operation.