Types of electric water heaters

The most economical way to heat cold water is to use a gas water heater, but in most cases this heater simply cannot be installed. In multi-storey buildings, special systems for the disposal of natural gas combustion waste are most often absent, and many private houses and summer cottages are not supplied with gas. Therefore, in this case, the installation of electrical appliances for obtaining hot water has no alternative. All electric water heaters are divided into only two types: storage (boilers) and flow-through. Below we will briefly review the principle of operation of each type separately.

- Electric storage water heater (boiler). This device is most often called a boiler. The device is a simple water tank with installed heating elements (TENs) and electronic or mechanical control systems. The container itself is thermally insulated from the external environment, which allows significant energy savings. The principle of operation of the storage water heater is static. The tank is filled with cold water and it is heated by heating elements. The whole process of heating and maintaining the required temperature takes place under the control of the automation unit.

- Flowing electric water heater. The principle of operation of the instantaneous water heater is dynamic. This device does not have a cold water storage tank. The process of heating water by heating elements occurs in special pipes and coils with a constant flow of water through these elements. As in storage systems, the principle of mechanical or automatic control using an electronic unit is implemented in instantaneous water heaters. For rapid heating of a strong flow of water to the required temperature, the instantaneous electric heater must have sufficient power, which is a definite disadvantage.

These two types of electric water heaters can have different designs. There are devices with indirect heating, where heat energy is transferred to water through an additional heat carrier in a heat exchange module. In this case, the heating elements heat up a special liquid, which in turn transfers heat to the cold water in the heat exchanger. In addition, not only heating elements, but also other devices, for example, infrared sources, can be used as heating elements.

But all these devices are much more expensive, therefore, flow and storage water heaters with direct heating of water by resistance heating elements, that is, heating elements, are mainly used. Below we will take a closer look at the device, the principle of operation, the advantages and disadvantages of both types of electric water heating equipment. This will allow you to make the right choice of a device for uninterrupted supply of hot water to your home, office or utility room.

The main types of water heaters

There are three types of boilers in total:

Flowing. The water begins to heat up at the moment it passes through the tube with the heating element. This type is needed when hot water is not required very often and in a small volume. Otherwise, it will consume a lot of electricity.

Accumulative. By their structure, the heaters are somewhat reminiscent of a thermos. This means that the water remains hot for a long period of time after it has been heated.This indicates a low energy consumption of the boiler.

Combined. The heating element of this boiler operates at both high and low power levels. Due to the fact that the device can operate both storage and flow-through, a person can use hot water, even if the device is empty. There is one more difference in this type of boiler - a large capacity - up to two hundred liters of ode.

The most popular model of the Boiler is the storage type water heaters of 80 liters. They differ in various characteristics:

- form,

- power, etc.

The main part of the devices can respond to a drop in water temperature, and in automatic mode they turn on the heating element.

By appearance, there are 2 types of boilers: flat and barrel-shaped.

As for the latter, they can keep water hot longer due to their spherical shape. But they are very cumbersome for our apartments.

Flat heaters in this regard are much more profitable, since they are not very large in size and are simply installed anywhere in the house.

Flat electric heaters of 80 liters can be installed vertically or horizontally. This will depend on the availability of free space. Basically, boilers are installed vertically.

Storage water heater 80 liters vertical flat: structure

If you are interested in what constitutes an electric storage water heater 80 liters flat, then you will find information about it below.

Any of the water heaters consists of a metal container, which is installed on the wall using special fasteners, or mounted on the floor. The body of the water heater is made of durable steel, coated with a special type of enamel. This is necessary so that the body of the device can always remain cold. And on its surface it was impossible to burn. In addition, the use of steel as the main material for the manufacture of the case is a guarantee of the durability of the device.

Thermal insulation is located under the body of the heater. Basically, in the horizontal flat storage heater 80L, polyurethane foam is used for this purpose. A titanium tank is located in its layers. It is in it that the water is heated. Water enters the tank from the main water supply system through a hose supplied with the heater.

Water heating in a vertical or horizontal storage water heater of 80 liters is carried out using a heating element that has a serpentine shape. Some types of heaters have more than one heating element, but two at once. Basically, this feature can be found in heaters with a large volume. A magnetic anode is located near the heater, which protects the heater itself from various types of mechanical damage. In addition, it prevents limescale build-up.

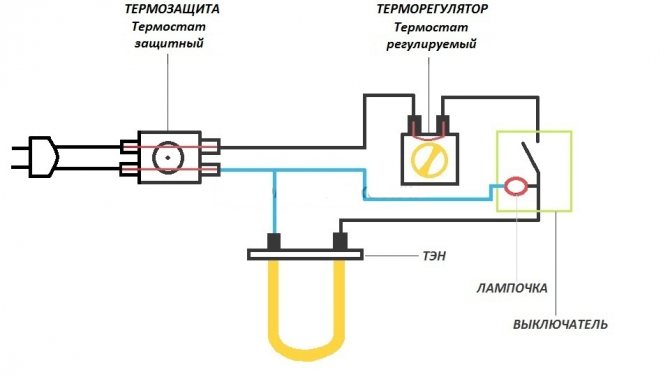

There is another main element of a water heater - a thermostat. This element is able to regulate the temperature of water heating, and does not allow overheating, it can maintain a given temperature mode. it is also capable of performing other functions that are associated with the transformation of cold water into hot water.

The principle of operation of the water heater

Any horizontal or vertical 80L storage type water heater operates as follows:

From the domestic water supply system through a special pipe, water enters the titanium tank.

- The system turns off automatically, the temperature of the coil starts to rise, after which the water begins to heat up.

- After the water reaches the desired temperature, the thermostat turns off the heater. this procedure saves electricity and avoids overheating of the entire system.

- Hot water, through a special outlet pipe, goes to your personal disposal. Or, more simply, in the shower, faucet, or heating system.

- Different models of water heating boilers may differ. such parameters as the time for heating water to the highest temperatures, the rate of water collection in the tank. But still, the basic principle of operation remains the same.

Storage water heater

The storage water heater device is quite simple. The main element of the device is a water tank made of stainless steel or aluminum. If the tank is made of plain steel, then its inner surface of the tank is coated with special materials that improve its performance and corrosion resistance. A heating module is installed in the storage tank, consisting of one or several heating elements. Heating elements can be "wet" or "dry". In the first case, the heating element is in direct contact with water, and in the second, it is placed in a tube that heats the water.

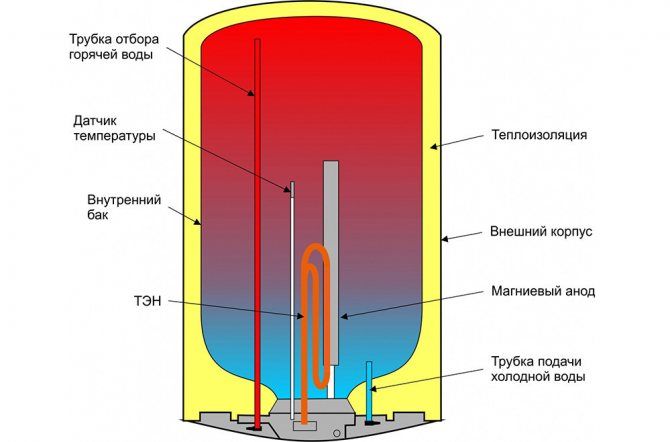

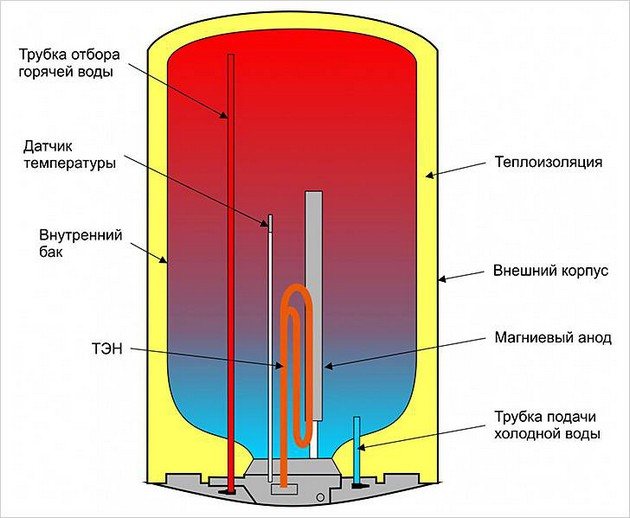

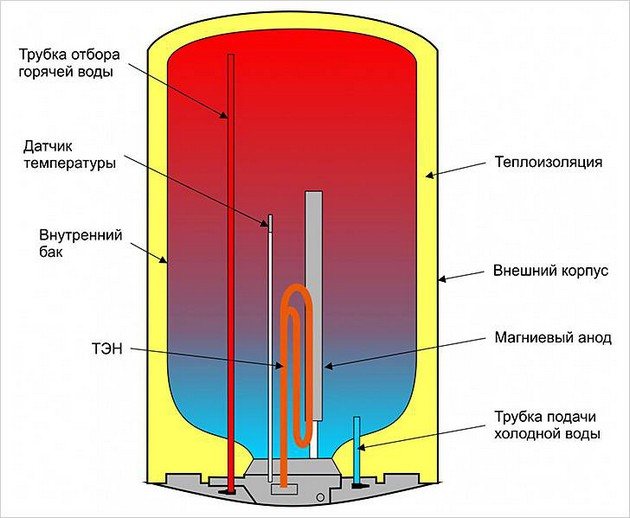

This whole structure is placed in an outer casing and insulated from it with a special thermal insulation material. A thermostat and other necessary sensors are installed in the tank, connected to the automation system and information modules. A control system, mechanical or electronic, is mounted on the outer shell of the device. Below is a classic diagram of a storage water heater in section with the minimum required set of elements.

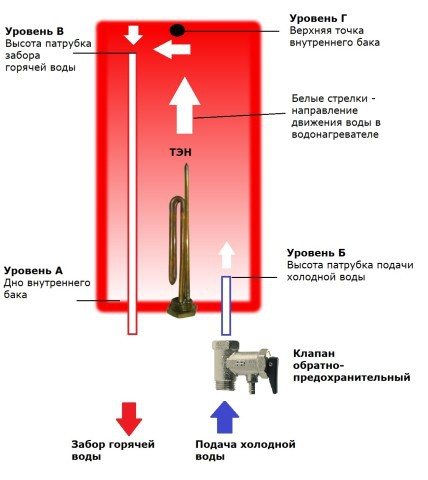

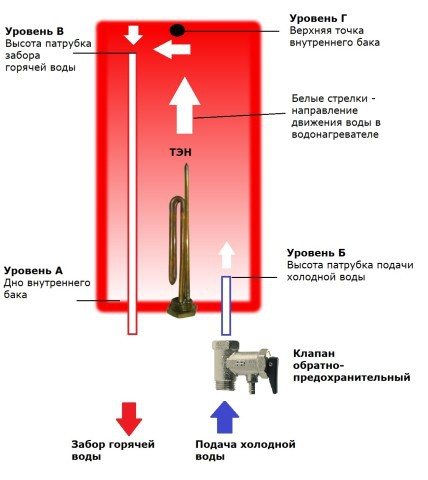

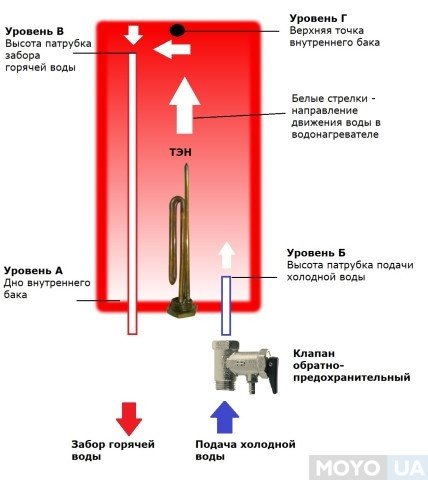

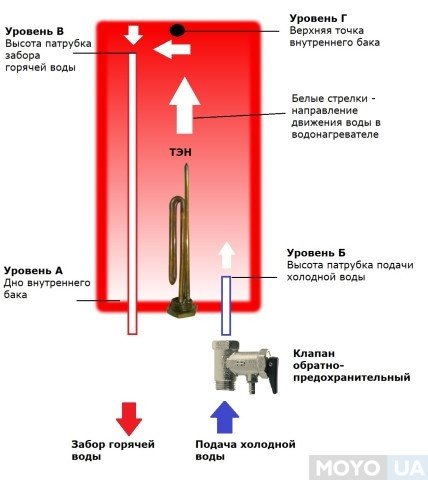

How does a storage water heater work? It's pretty simple! The principle of operation of the boiler is based on the properties of water with different temperatures. As we know from the school physics course, a warm liquid tends upward, and a cold one - downward. It is on this physical phenomenon that the work of all storage water heaters is built. Cold water is supplied from the bottom of the device and heated by a heating element. As it rises, it is removed from the tank through a high hot water intake pipe. The process itself is simple, but for the reliable functioning of the entire system, the installation of additional elements and systems both inside the tank and on the protective casing is required.

A magnesium anode is installed inside the storage tank, which is necessary to reduce the amount of free ions in the water. This element makes it possible to significantly reduce the corrosion of the internal parts of the boiler. And also a thermostat is installed in the tank, which allows you to regulate the water temperature and turn off the heating elements when the required temperature regime is reached. The whole process of heating and withdrawing hot water in the boiler is shown in the following figure.

In most electric storage water heaters, temperature sensors are installed, with readings displayed on an electronic display or a mechanical thermometer. Cold water is supplied through a tap with a safety check valve. Boiler operation modes are controlled by both electronic modules and mechanical regulators in simpler models. The advantages of storage electric water heaters include the ability to heat large masses of water and low energy consumption, and the disadvantages are high cost.

Storage water heaters, how they work

- Video creator: Marat Ishmuratov

- Author's channel: https://www.youtube.com/channel/UCyrdKMbXbRXONaCrEY0rnPg

- Video:

We will tell you about storage electric water heaters, show the design of internal tanks, tell you how they are arranged inside and how they work.

- Appearance of the water heater

Externally, a water heater can look different - it can be round, square, oval, flat. Next comes a small layer of thermal insulation and an internal tank where water is heated.

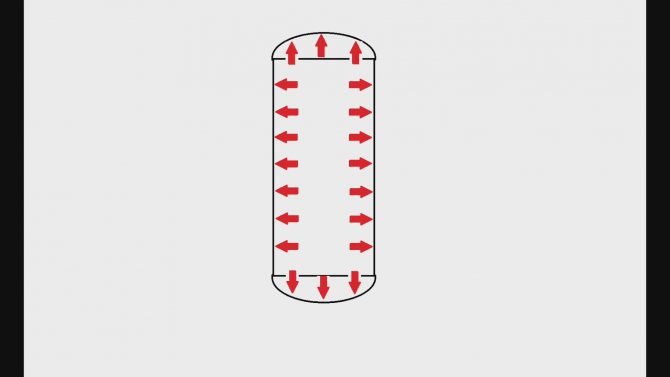

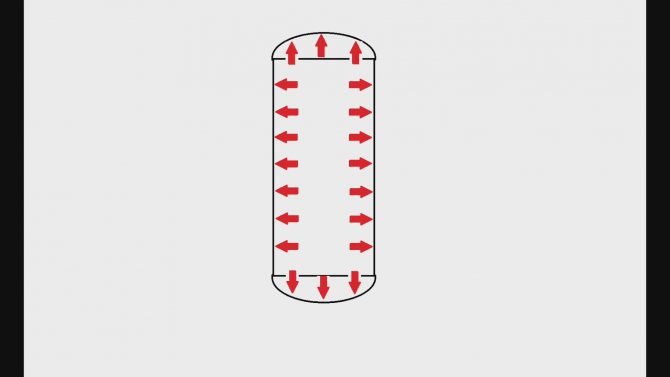

But no matter how the water heater looks externally, and its internal tank is always round.This is necessary because water is poured into the tank under pressure, and when heated, it also expands, while the pressure increases. Only in a round tank is the pressure evenly distributed on all walls.

The upper and lower parts of the water heater, as a rule, are also made semicircular. This is done for the same purpose - in order to distribute the pressure as evenly as possible.

Let's take a quick look at what happens to the inner tank if you make it square. When the pressure in the inner tank starts to rise, the corners of the square tank will remain practically motionless, but the walls of the tank will begin to swell like a ball.

As the water heats up and cools down, the pressure in the internal tank will constantly change. From this, the tank will constantly inflate and deflate, and very quickly collapse.

Here's an example. Almost square water heater with rounded edges. However, if you look inside the water heater, you will see that the internal tank where water is poured into will be absolutely round.

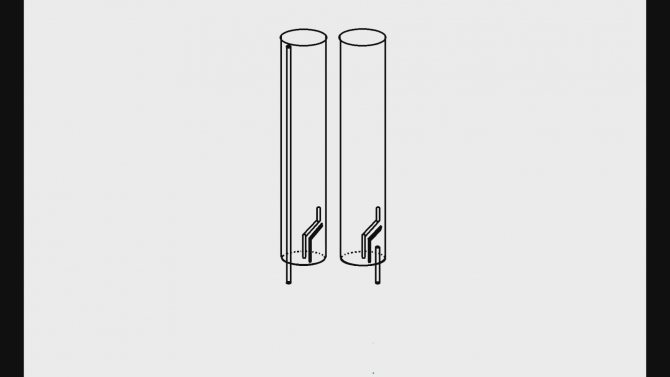

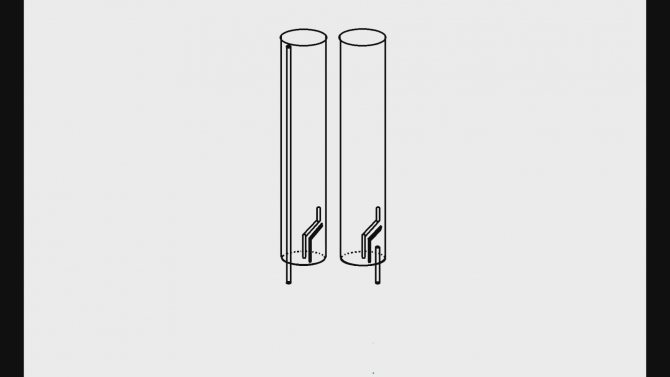

- Internal tank device

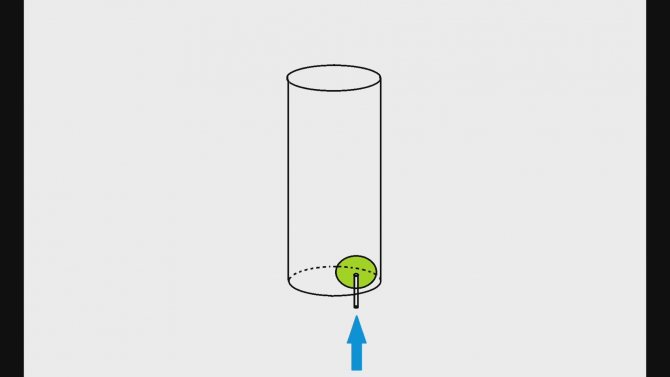

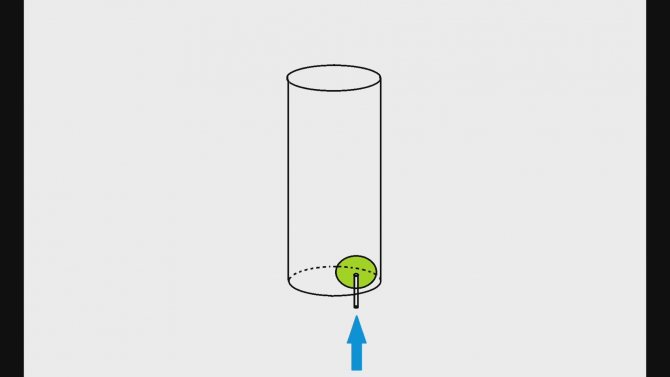

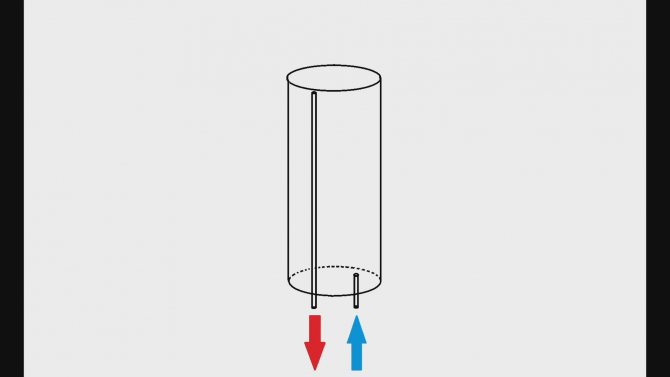

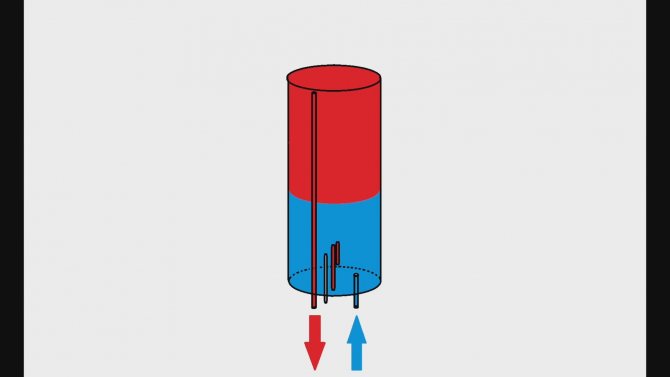

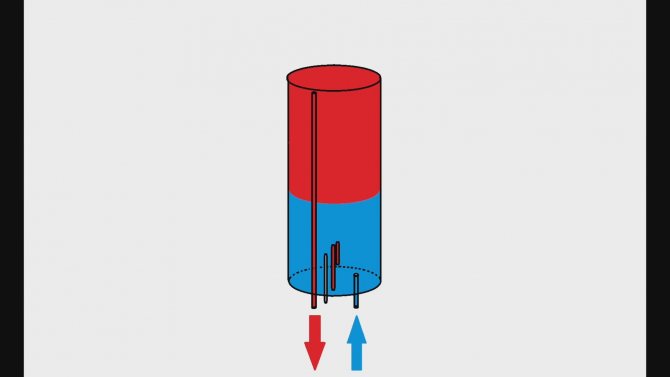

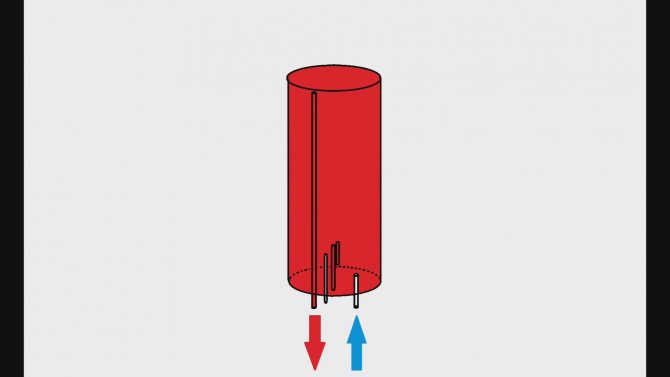

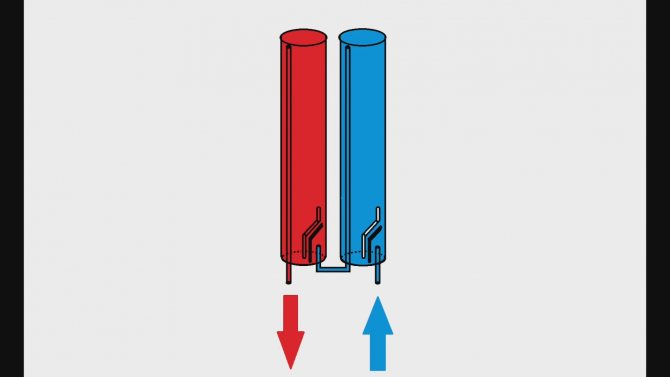

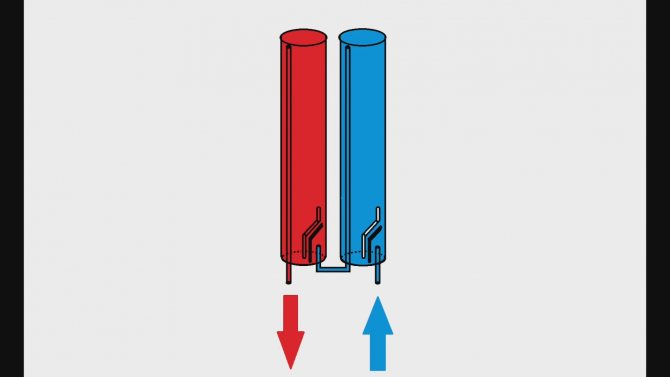

Let's look at how the internal tank of a conventional vertical classic water heater works. So, all water heaters have a cold water inlet. The supply takes place in the lower part of the storage water heater.

Also in the design of the tank there is one more branch pipe through which hot water comes out from the storage water heater.

In order to take only heated water, water is taken from the top of the tank. To heat water in all water heaters, an electric heating element and a sleeve with an immersion sensor for measuring the water temperature are installed.

- How does a water heater work

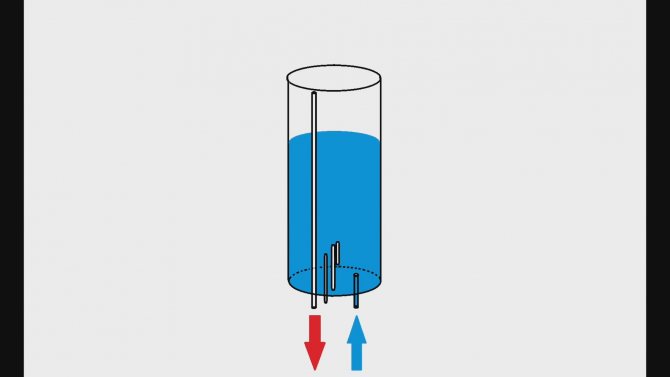

We fill the water heater with cold water.

After filling, we turn on the water heater, and the heating elements begin to heat cold water. According to the laws of physics, hot water is lighter than cold water, so the accumulation of hot water in the tank starts from the top.

After full warming up to the set temperature, the immersion temperature sensor gives a signal to the water heater thermostat to turn off the heating element.

- Universal water heaters

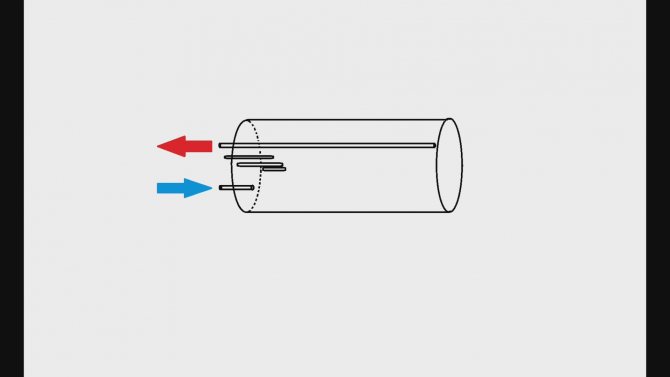

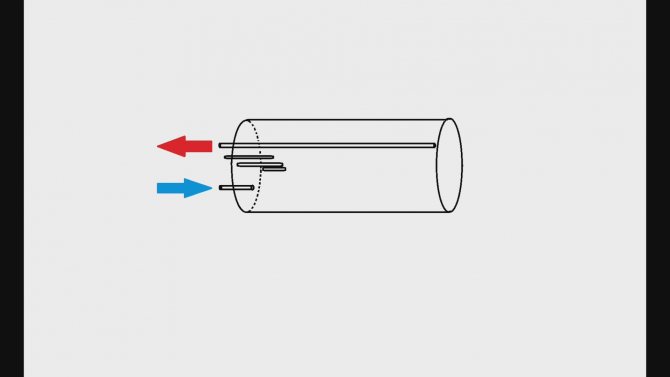

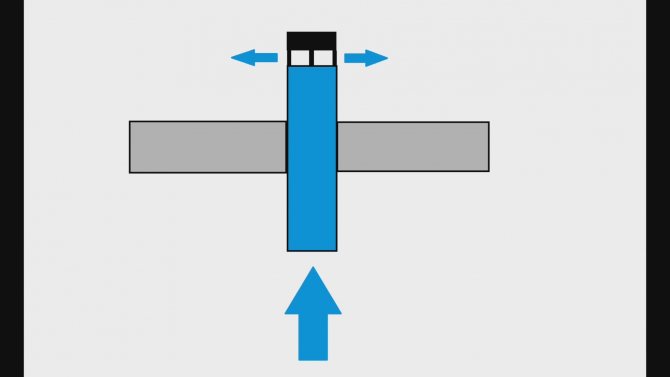

Some models of water heaters have the possibility of universal installation. They can be hung both vertically and horizontally.

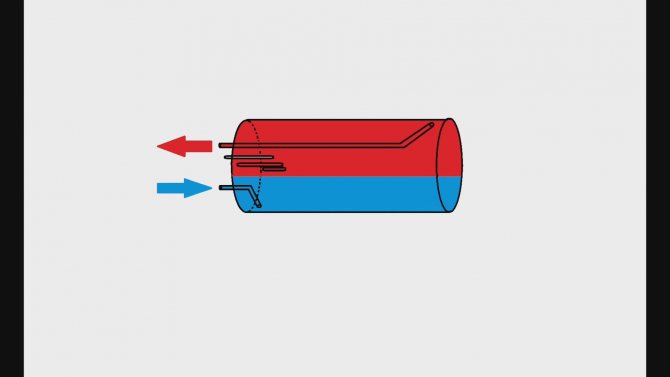

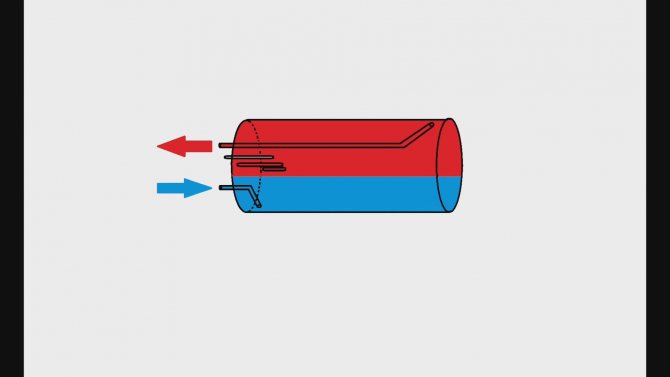

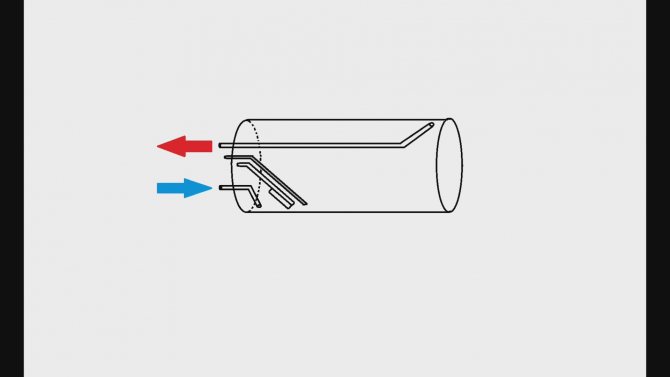

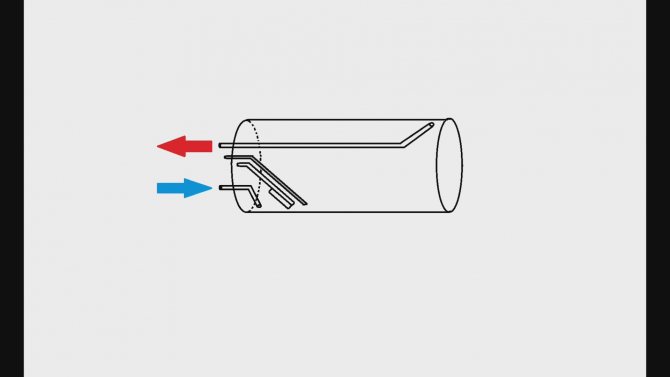

For this, some changes have been made to the design of the water heater. The branch pipe through which cold water flows inside the tank is turned down, the branch pipe through which hot water comes out is turned up. As a result, cold water enters the lower part of the water heater, and hot water is drawn through the upper part of the tank. The location of the heating elements and the immersion sleeve where the sensor is inserted will also differ. If you leave them as they are, then the hot water will be heated exactly to the level of heating elements with a submersible sensor, and in the lower part of the tank the water will remain unheated.

In order to exclude such a possibility, the heating elements themselves and the immersion sleeve are installed with a slope in the lower part of the tank.

After making such changes, the water will warm up completely, and the water heater will work in the same way as with a vertical installation.

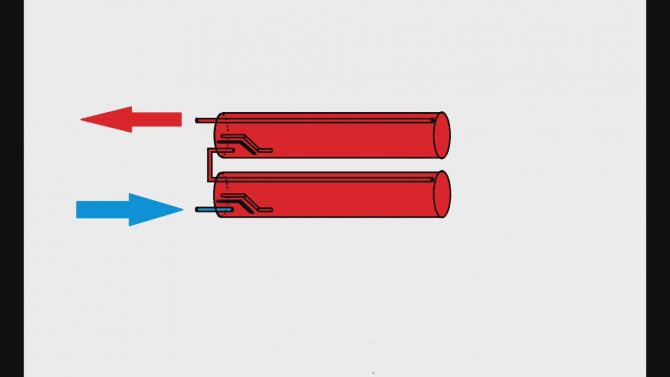

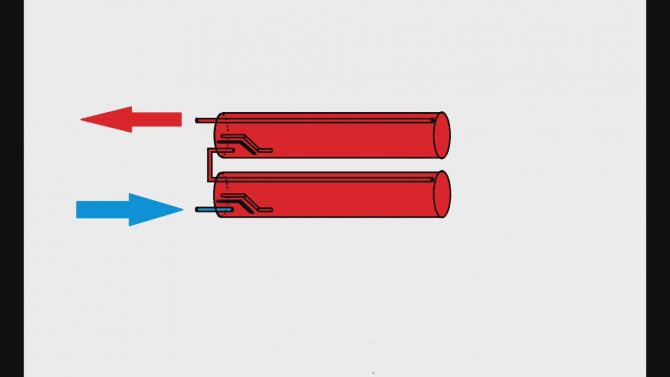

Cold water, as a rule, enters the water heater with a high pressure, and so that cold water does not mix with already heated water, the following flow distributor is installed in the tank:

Thus, the cold water that enters the tank is distributed only in the lower part of the water heater and practically does not mix with the already heated water.

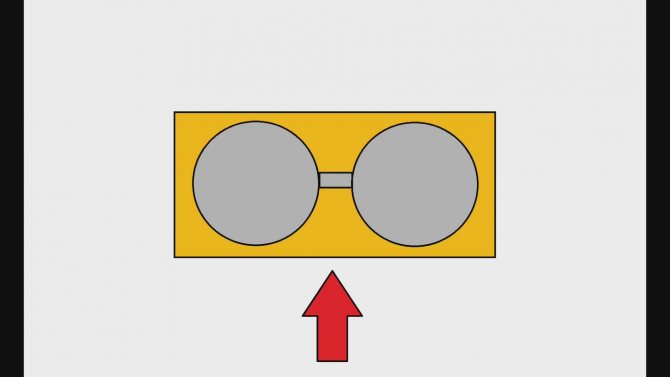

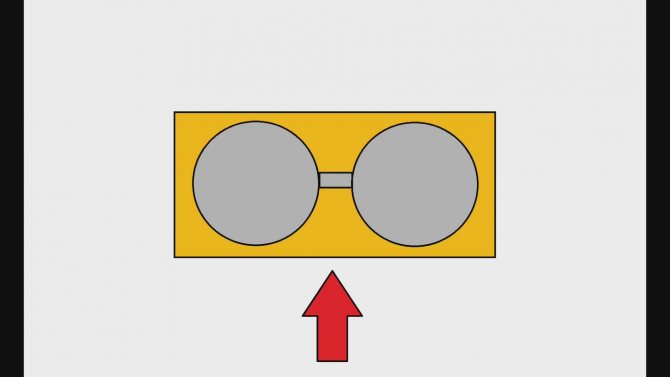

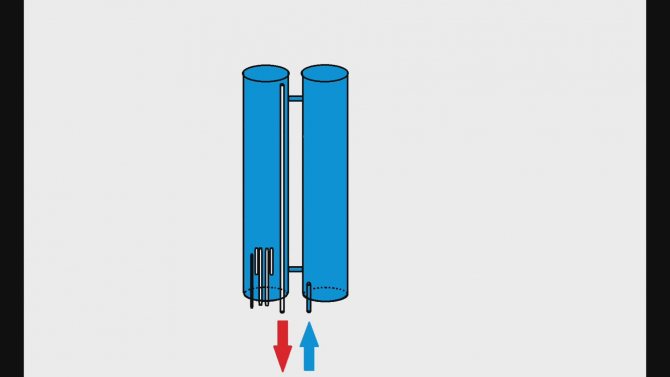

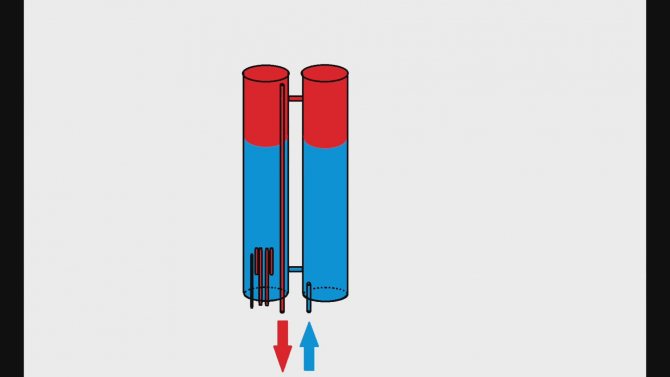

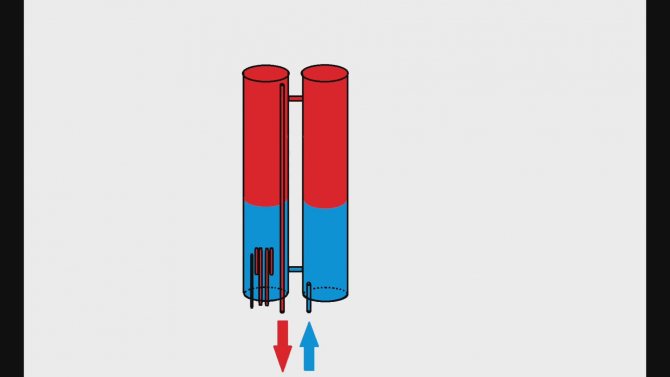

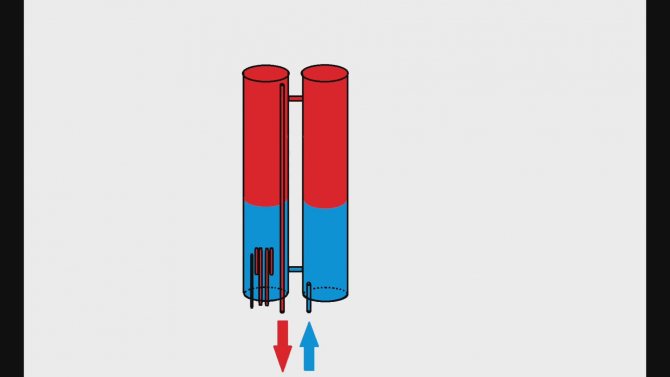

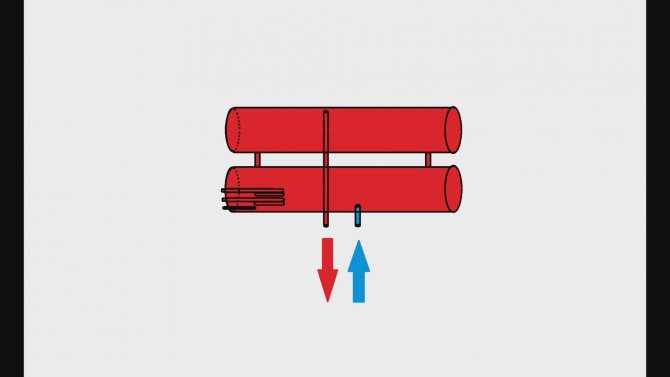

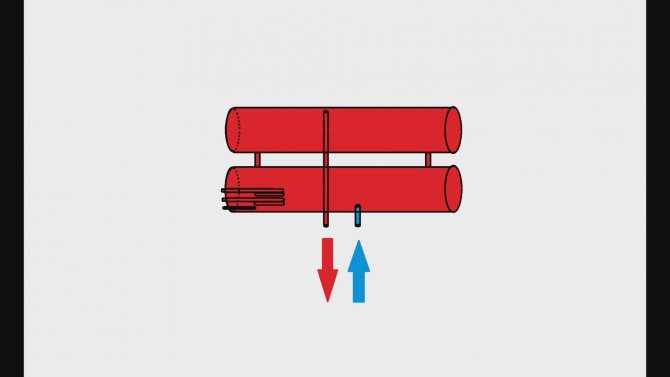

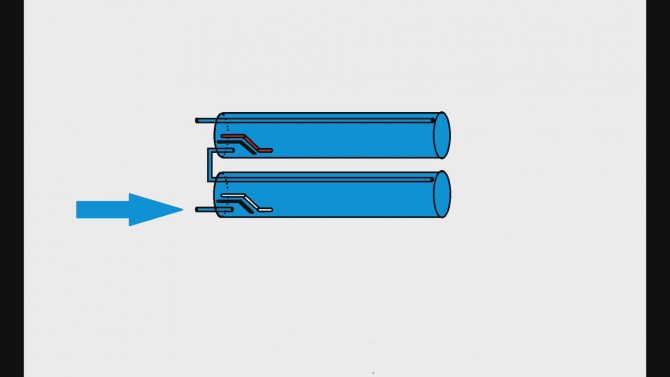

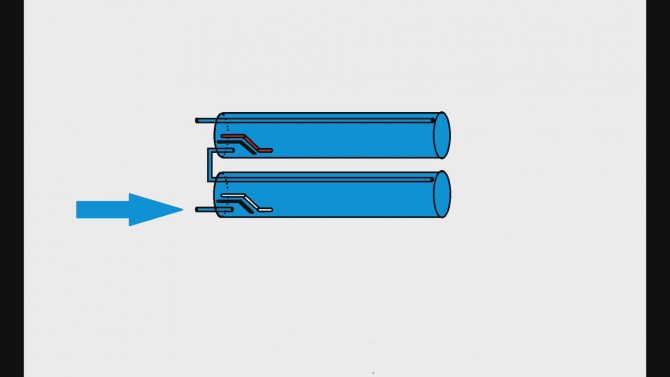

- Flat water heaters, their structure and operation

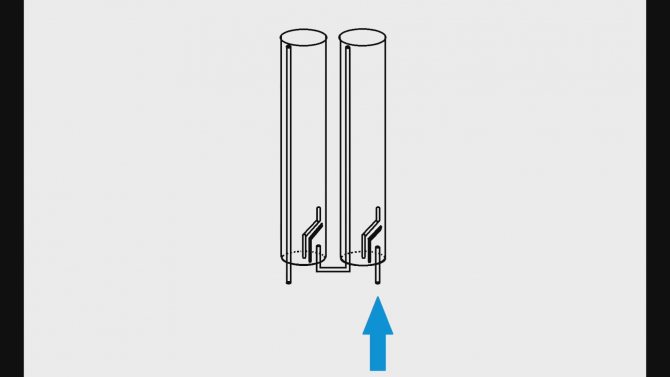

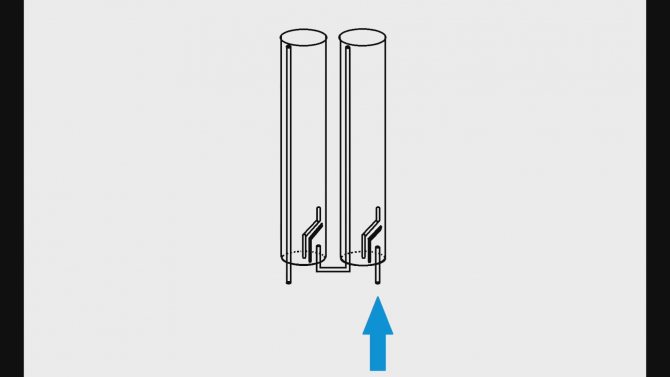

Next, consider flat water heaters and their structure inside. In order to make the water heater flat, the manufacturers had to install two whole round tanks.

Internal tanks are made of stainless steel or ordinary steel with a protective coating.This is how the two internal tanks look like, in this case made of stainless steel.

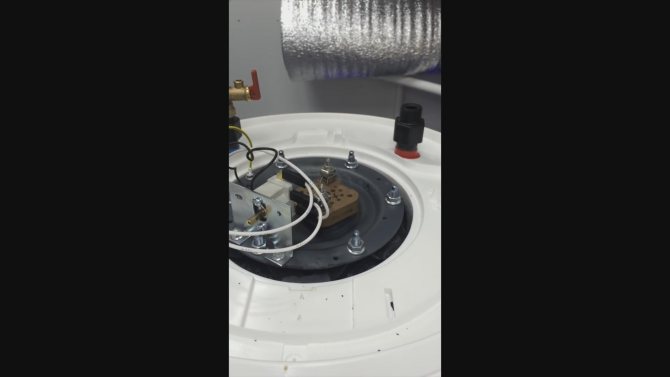

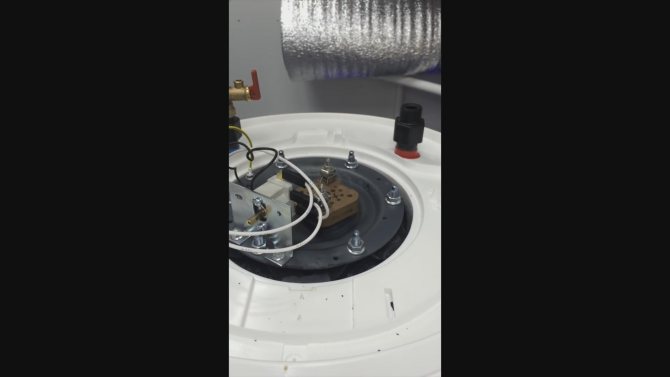

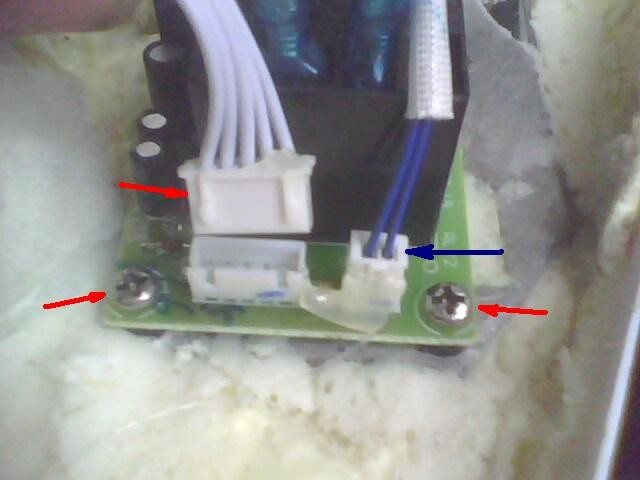

In the lower part there is an inlet-outlet and a hole for installing the heating element. Let's take a look at how these heaters are arranged internally. As in all water heaters, they have one or two heating elements. Together with the heating elements, a sleeve for an immersion temperature sensor is installed. In this case, all this is installed in the second tank on the right.

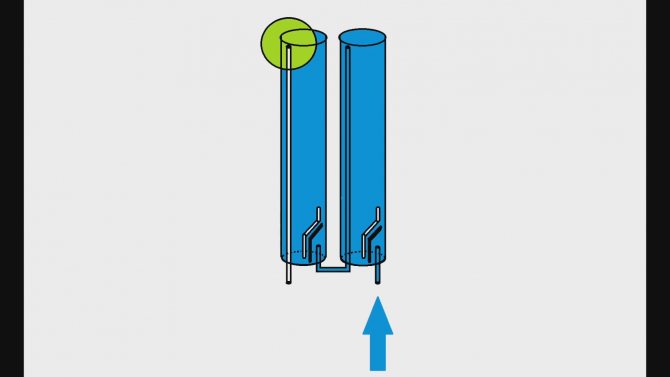

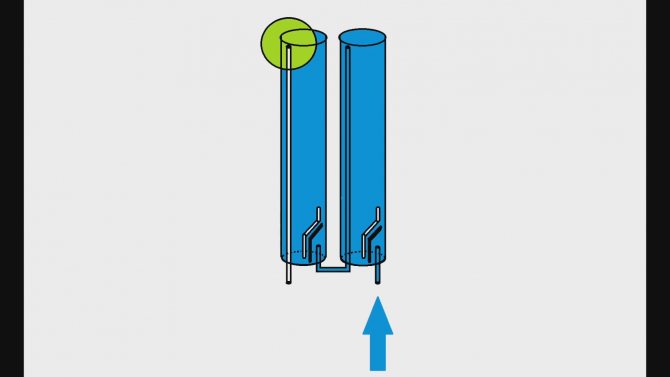

Cold water is supplied to the first tank, hot water comes out of the second tank. We fill the water heater with cold water, turn on the heating elements.

The heated water begins to accumulate in the upper part of the tank, where the heating elements are installed.

Since both tanks are connected to each other at the top and bottom, water overflows from the second tank to the first and from the first to the second.

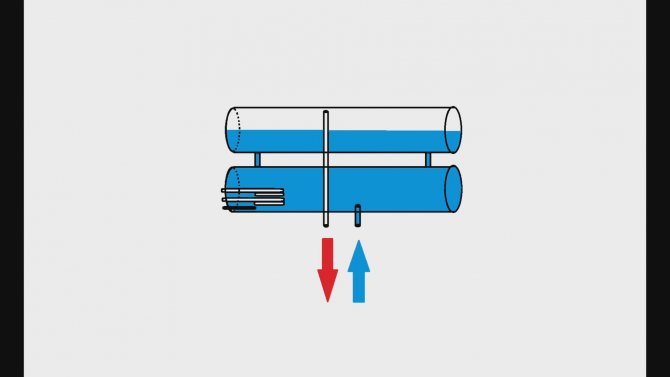

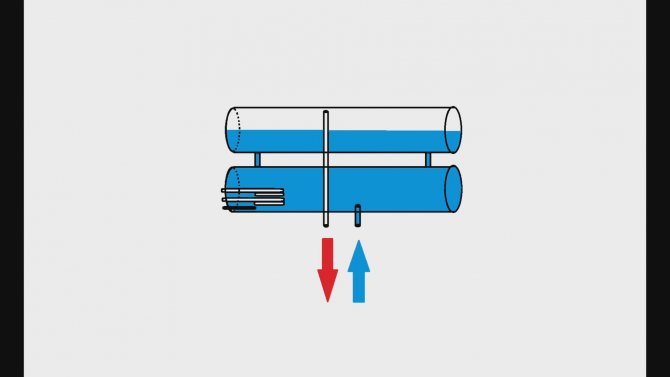

Thus, the water is fully warmed up in both tanks. Flat-plate water heaters with two tanks in this design can only be installed in a vertical position. They cannot be installed horizontally, they will not work. There are separate models for horizontal installation. Their construction inside is slightly different from models with vertical installation. The inlet and outlet for such models of the water heater is located in the lower tank. Cold water is supplied to the lower tank, hot water is taken from the upper tank. Some models of water heaters still have a third hole for installing a magnesium anode. The heating elements are also located in the lower tank, and a sleeve for the temperature sensor is also installed there.

So, we fill the water heater with water.

The lower tank is filled first, then the upper one. We turn on the heating elements. The water begins to warm up, hot water begins to accumulate in the upper tank, then the lower tank gradually warms up. That's all - you can use the water heater.

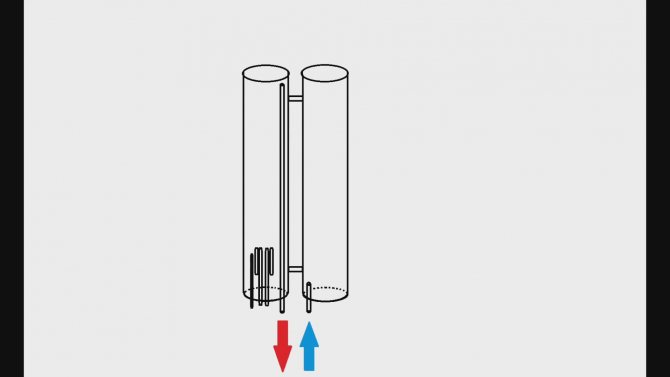

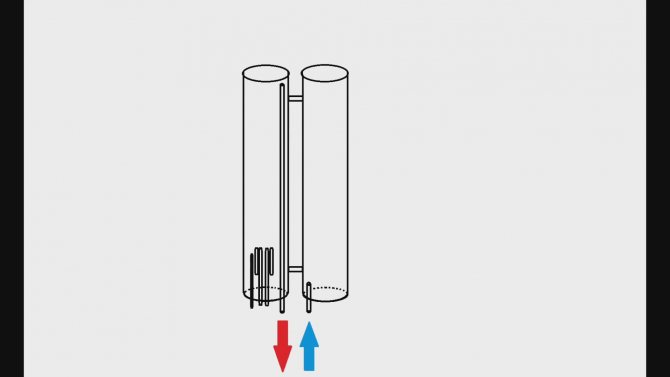

- Flat water heaters with universal installation

The double tank flat water heaters are available in universal mounting models. They can be hung both vertically and horizontally. In the section it is very clear that each tank has its own heating element and its own separate temperature sensor.

Universal water heaters have a few more differences compared to conventional flat water heaters. Whereas in conventional models two tanks are connected at the top and bottom, there are no such jumpers in universal models.

Instead, there is another tube in the first tank from top to bottom. This tube is through, it has an outlet at the bottom of the tank. This tube serves as an outlet for heated water from the first tank. Next comes the overflow tube that connects the first and second tanks.

In operation, such water heaters also differ slightly from simple models. When water is supplied to the water heater, the first tank is first filled, then the water enters the upper part of the branch pipe and enters the second tank through the overflow pipe.

Then you can use the water heater. Such water heaters have a very useful function: you can turn on only half of the capacity.

Thus, only one tank will be heated at the water heater. If you turn on the second heating element, then the water will be heated in both tanks. Such water heaters can be installed both vertically and horizontally. One note: they can be rotated either only to the right or only to the left. Be careful when choosing them. As a rule, information on which way the water heater can be turned is indicated in the installation instructions. The principle of operation with a horizontal installation is practically the same as a vertical one.

The first tank is filled first, then the second. In the same way, you can turn on one heating element for half the power to warm up one tank, or full power to warm up both tanks.

- Construction of heating elements

Let's briefly talk about the design of heating elements that are installed in electric storage water heaters.

Most often, one or two heating elements of different capacities are installed.

Heating elements, as a rule, are installed directly into the tank itself and have direct contact with heated water. There are water heaters with so-called dry heating elements, which do not have direct contact with water.

Such heating elements are in a special protective capsule.

Teng is inserted directly into the capsule itself, the teng itself warms up, then the capsule, and from the capsule, from this sleeve, the water itself, which is in the water heater, is already warming up. Such heating elements are considered more durable, since they do not have direct contact with water, and the service life of such heating elements increases dramatically.

Even if such a heating element fails, it is very easy to replace it - no need to drain the water, unscrew the flange. Ten is simply removed, and a new one is inserted in its place.

Instantaneous water heater

The device of an instantaneous water heater is completely different from the operating principle of storage equipment. This device does not have a tank for storing water, and it is heated with a constant flow of liquid through the heating module. As such a module, a structure made of pipes with heating elements is used, which can be located both outside and inside the structure. The best material for making a heating module is copper, but in cheaper models stainless steel or aluminum can be used.

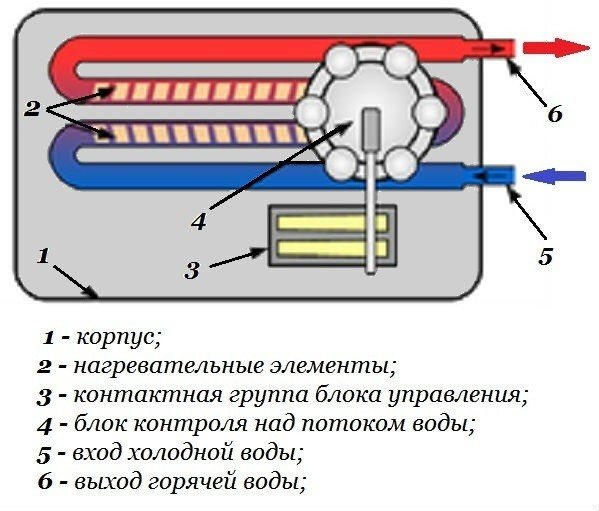

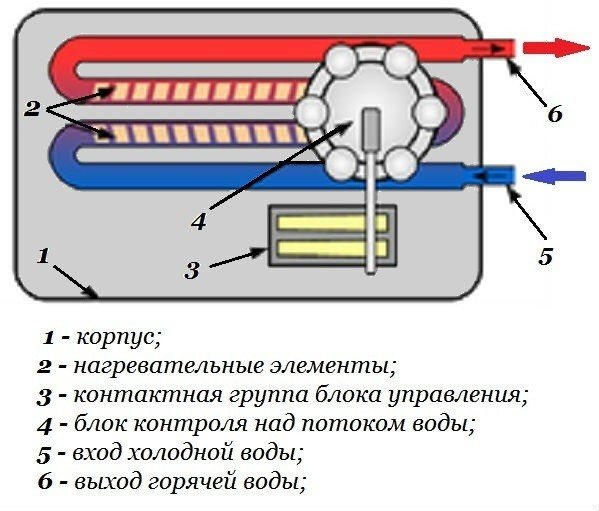

In addition to the module for heating water, the device includes various additional devices. A water flow sensor is required to determine the minimum water pressure at which the water heater can be operated. Temperature sensor, temperature controller (thermostat) are designed to control operating modes. A thermal fuse shuts down the system when the maximum possible water flow temperatures are exceeded. The picture below shows a classic cross-sectional diagram of an electric instantaneous water heater.

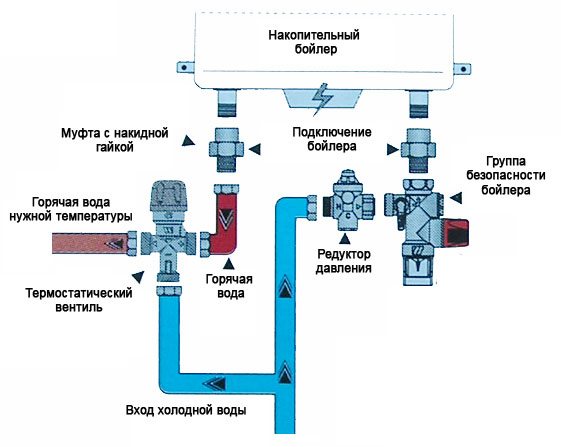

Diagram of the storage water heater device - boiler

A storage water heater (boiler) externally looks like a closed container, most often of a cylindrical shape. A storage tank is located under the decorative outer cover, into which water is collected for heating. A heat insulator is located between the tank and the cover, which limits heat loss from heated water.

Picture 2. Diagram of a flow heater.

Cold water enters the tank through an incoming cold pipe to its bottom. A heating element is located inside the boiler, which works on the principle of a boiler: it heats up by itself and therefore heats the water around it. The heated liquid is taken from the top of the tank (warm and hot water is lighter, it rises upward, so it must be taken from the top). Most often, the outlet of the hot pipe is located at the bottom, that is, the pipe takes water from the top of the tank and through the tank lowers it down to the outlet located there.

A thermocouple is installed inside the water heater, which automatically turns on and off the heating (operation of the heating element) depending on the temperature of the water in the tank. The temperature value at which the heater is de-energized and stops heating the space around it is set on the control thermostat, which is usually located at the bottom of the boiler and has knobs for setting the temperature level outside the tank.

Often, an air vent (in the upper part of the storage tank) is installed in the design of the water heater. Its purpose is to release (bleed off) the pressure generated when water is heated in a closed volume. The air vent works in manual mode, that is, not automatically by itself, but only in the presence of a person, with his hands.

A mandatory additional element in the design of the water heater is a safety (or emergency) valve. This is an automatic pressure relief device. It is located on the cold inlet pipe.

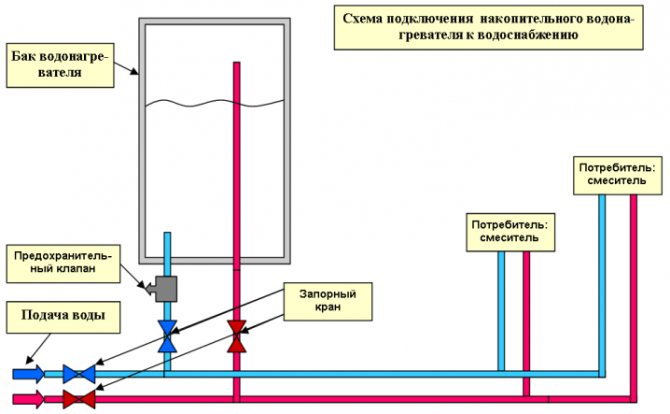

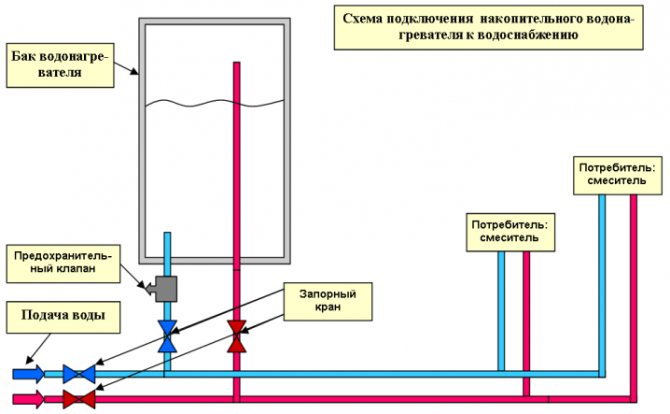

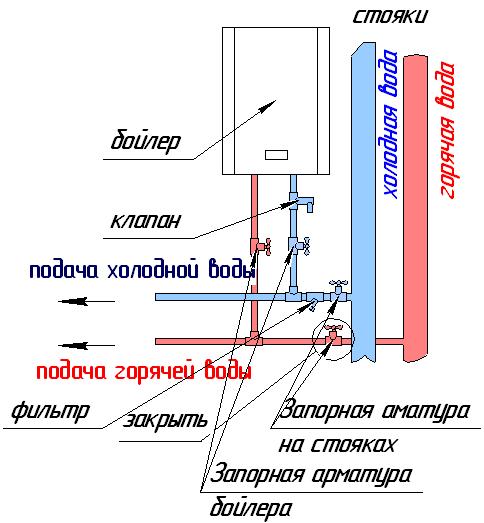

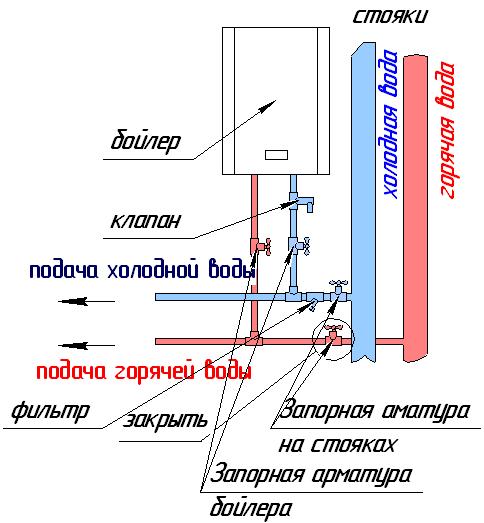

Storage water heater connection diagram.

The device of the safety valve ensures the dripping and percolation of water when the pressure rises above 7 atmospheres. For ease of use, the emergency valve is supplied with a hose that brings water into a nearby container or directly into a sink (bathtub, toilet bowl).

For the convenience of carrying out preventive work, repairs, a drain is installed at the water outlet from the tank.

A schematic diagram of the storage heater is shown in Figure 1, where its internal structure is shown in section.

All of the above elements can be made of various materials, with different characteristics of durability, reliability and cost. The variety of structural elements forms a wide selection of storage boiler designs.

Electric water heater market overview

Currently, there are more manufacturers, both domestic and foreign, on the Russian market for electric water heating equipment. Of course, mainly foreign manufacturers such as MTS and Lorenzi Vasco dominate, but you cannot call their products pure imports. Most companies open their own full-cycle production facilities in Russia, with the manufacture of basic components. This allows you to reduce the cost of production and make it available to a wide range of buyers. One of these companies is the Italian corporation Thermex, whose products have practically become a Russian brand.

For more than twenty years it has been successfully working in Russia, opening its own factories and providing our market with high quality electric water heaters. The lineup from this manufacturer includes all types of electrical equipment for water heating. The popularity of the Termex water heater among consumers is very high due to the innovative ideas used in its manufacture. The principle of operation of the Termeks water heater, regardless of the type of device, does not differ from similar products from other manufacturers. But it should be said right away that the company's products have won the trust of the Russian buyer with their technical characteristics and affordable prices.

Why are water heaters from the "Termeks" corporation so good? Everything is very simple! The range of products is very wide and allows almost any consumer to choose equipment for heating water according to their needs. Electric storage water heaters Termeks are produced in a wide range of internal volumes from 10 to 300 liters. Flow-through heaters of various capacities allow you to almost instantly heat flowing cold water to the required temperature.

Other advantages of Termeks electric water heaters include the following technological and design features:

- the range of storage water heaters consists of both round and flat models of various sizes with a laconic design;

- high-quality thermal insulation of products and automatic control of operating modes can significantly save energy;

- in various models, both electronic and mechanical control are used, which makes it possible to optimize the entire process of heating water;

- storage water heater tanks are made of special stainless steel with high corrosion resistance;

- in instantaneous water heaters, the heating module is completely made of copper, which increases its reliability and durability;

- in some models of storage water heaters, the inner surface of the tanks is covered with bioglass porcelain, which completely eliminates the corrosion of the tank.

In addition, the product range includes electric water heaters with a combined water heating system.

How to properly use a new boiler?

Example 2 of connecting an electric water heater.

The boiler is a large water tank. Inside the unit there is an element for heating the liquid. The water is heated thanks to a heat exchange device (water or steam). In the heat exchanger, heated water constantly flows in a closed water supply circuit. These water heaters are sometimes referred to as indirectly heated water heaters. Sometimes heating is done with a gas burner. In order to properly use the new device, be sure to read the instructions.

The device must be installed by specialists, and the very first start-up must take place in their presence. In turn, you must make sure that the device is installed by specialists with high quality. To do this, make sure there are no leaks. First, disconnect the boiler from the electrical network and only then fill it with cold water.

To understand that the storage water heater is completely full, you first need to open the hot water tap at the boiler. This can be seen after the water flows from the tap. Then the valve should be closed and the outside of the unit should be examined. If no problems are found, you can safely connect it to the network and set the device to the required operating mode.

The device and the general principle of operation of the storage water heater

The general device of a storage type water heater is the same for any model. The boiler consists of a water tank, which is enclosed in a decorative casing, and a heater is laid between them. It turns out like a thermos. The main difference between storage boilers is what kind of heater they have: an electric heating element or a gas burner.

There are storage water heaters of indirect heating, where a coil connected to the heating system serves as a heater. Such boilers turned out to be practically not in demand. Heating does not work all year round, which means that a person does not have the opportunity to use hot water in summer.

Storage heaters differ according to the type of installation. Vertical boilers take up a lot of space, which is why they are placed in a spacious room. A horizontal water heater is more suitable for a small room. The last option is inconvenient in terms of use. In the case of a horizontal boiler, the hot and cold layers of water are quickly mixed. As a result, when you open the tap, boiling water flows, and after about a minute, cooler water begins to flow.

General device of the boiler

Let's look at what the diagram of a conventional storage type water heater looks like:

- The boiler is based on a tank. In household models, its capacity is limited to 300 liters. The tank is made of stainless steel or steel. To prevent the metal from rusting, glass enamel, glass porcelain or titanium spraying is used as an internal coating.

- The water tank is enclosed in an external decorative casing. It can be made of stainless steel, ordinary enamelled steel or plastic.

- The space between the storage tank and the outer casing is filled with heat-insulating material - polyurethane foam.

- The front area of the outer casing of the water heater is equipped with a thermometer.

- The heart of the storage boiler is the heater. An electric water heater operates from a built-in element - heating element (tubular electric heater). Gas storage water heaters are equipped with a burner and a chimney.

- Hot and cold water pipes come out at the bottom of the storage boiler. A safety valve is installed on the cold water pipe, as well as a check valve. The first one opens from excess water pressure inside the tank. The second - does not allow water to leave the tank in the absence of pressure in the water supply system.The hot water pipe is connected to the intake pipe.

- The electronic unit is designed to control the operation of the storage water heater. It receives a signal from a thermostat, the sensors of which are installed inside the tank.

- The magnesium anode protects the steel tank of the boiler from electrochemical corrosion by releasing ions.

Installation and operation of any storage water heater does not cause any difficulties for the user. The device is attached to the wall with brackets. The supply pipe can only be connected to a cold water supply. This is the principle of the boiler operation, since it is cold water that heats up in it. If the input of the storage water heater is connected to the centralized hot water supply of the apartment, then the correct temperature achievement after supplying the hot water to the tank will become impossible.

Principle of operation

The basic principle of operation of a storage water heater is the layer-by-layer separation of liquids of different temperatures. According to the law of physics, warm water is at the top, and cold water is at the bottom. For a complete understanding of how the boiler works, we will consider all the steps in order:

- When you open the water tap, water starts to flow. The upper layers of hot liquid from the boiler tank are directed through the intake tube into the pipeline.

- The pressure inside the water heater tank becomes less than in the supply water pipe. The non-return valve opens and the cold water supply begins. When the pressure of the water supply and inside the tank is equal, the check valve closes. During make-up, cold water does not mix with hot water thanks to a divider installed at the end of the supply pipe.

- A sensor signals the entry of cold water into the water heater tank. He instructs the control unit to turn on the heating.

- Electricity is supplied to the heating element, and the water is heated to the set temperature. With a gas water heater, gas is supplied to the burner instead of electricity. When the water reaches the desired temperature, the thermostat turns off the heating element.

Selection of a storage water heater for your apartment.

The choice of a water heater begins with the volume of the container! This capacity is selected based on the number of people living in an apartment or in a private house who will need to take a shower in the morning. If the heater is used for kitchen purposes, then 15 - 30 liters will be enough. For the bathroom, the principle of volume selection is as follows:

- A tank of 50 liters will be required for two people

- For three, 80 liters is the best choice

- for 4 or more people, a water heater of 100 liters or more is required

What is the capacity of the water heater ??

The power of most household appliances ranges from 1.5 to 2.5 kW. Water heaters with such a capacity can be plugged into an outlet without laying a separate line from the panel and without installing a separate machine. On many models, manufacturers install power cords with an RCD (residual current device) installed. RCD protects the consumer from electric shock due to breakdown on the case. According to the laws of physics, the greater the power of the heating elements (most often heating elements), the faster the water in the tank will be heated. I.e if you need to use hot water often, then you should choose a power of 2-2.5 kW, otherwise 1.5 kW is enough.

Electrical safety for the water heater.

A storage water heater is a device that can shock a person. Therefore, when installing it, it is important to observe the following simple rules:

- The electrical outlet used to connect the water heater must have a cover. The socket housing must be sealed.

- The storage water heater must be connected via an RCD !!! For many budget models of water heaters, an RCD is not included in the kit and must be purchased separately.

- If there is no RCD, but there is a ground loop, then the water heater can be grounded.A ground loop is expensive. In multi-storey buildings, it is most often absent, and it is absolutely impossible to ground the water heater through heating pipes, water pipes or (God forbid!) Gas supply! This can cause premature failure of metal pipes due to corrosion.

The appearance of the residual current device Now I'll tell you a little about what an RCD is (stands for residual current device). RCD is a device that turns off the power of the device if the value of the differential current exceeds a certain limit (most often 30 or 35 mA). Simply put, inside the RCD there are two coils - one each current flows into the device, and the other flows out of the device. If there is no leakage, then these currents are practically equal to each other, and in the event of a leak, a difference appears, which forces the RCD to turn off the power. The residual current device will operate the same regardless of whether there is a "ground" in the outlet to which the water heater is connected.

Vertical, horizontal and "universal" tanks.

For the needs of consumers, manufacturers of water heaters make different installation options. The most popular are "vertical" tanks (see picture below).

Horizontal and vertical water heaters

In vertical tanks, due to the smaller contact area of hot and cold water inside the tank, the amount of hot water will be greater than in horizontal tanks. This means that, all other things being equal (volume and power), the vertical version will give more hot water. There are also tricky units that can be installed both vertically and horizontally (Ariston has a model called Velis).

Flat or round water heaters ...? That is the question!

In shape, the water heater can be flat or round (cylindrical if you speak correctly). They are arranged a little differently, but the essence is the same! Most often, the choice of form is determined by the preference of the buyer, or by the dimensions of a particular tank. For the price, flat water heaters are significantly more expensive than round ones. This is due to the fact that there are two water-containing containers inside the flat device, and not one, as in its round counterpart. In addition, in almost all flat devices, the inner tank is made of stainless steel, and among the cylindrical water heaters, most of them have a container, which is covered with enamel from the inside. I will say right away - stainless steel lives longer than enamel... For example, the Termeks company has a 7-year guarantee for stainless steel, and 3 years for enamel. I advise you to choose a stainless steel tank.

The device and principle of operation of an electric boiler

Electric water heaters are considered the most popular among residents of apartments and private houses. The popularity is due to the ease of installation and operation. The diagram shows a sectional view of the storage water heater device. Let's take a look at what an electric boiler looks like from the inside:

- We will begin to consider the device of a storage electric water heater with a tank. It is round or oval in shape. The tank is enclosed in a decorative casing. The inner space between the two containers is filled with polyurethane foam.

- A feature of the electric water heater device is the presence of a heating element. The element is installed at the bottom of the boiler tank on a flange connection.

- The thermostat controls the switching on and off of the heating element. Any storage water heater works without exceeding the maximum permissible temperature. For electric boilers, this figure is 75 o C.

- The water heater is protected. In case of failure of the thermostat, the heating element will be de-energized when the critical water temperature reaches 85 o C.

- Hot water is drawn through a pipe, the end of which is brought out to the top of the boiler tank. A branch pipe is installed at the bottom of the tank for feeding cold water.

- The magnesium anode protects the tank body from corrosion.After 2-3 years, the element collapses and needs to be replaced.

- The operation of the water heater is signaled by an indicator lamp.

Knowing how the boiler works, you can understand its work. Cold water enters the inside of the boiler tank through the pipe. The sensor sends a signal to the control unit, which, using a thermostat, supplies voltage to the heating element. The water is heated to the set temperature. The sensor gives a new signal and the thermostat interrupts the power supply. After drawing hot water, the cycle repeats.

Varieties of heating elements

According to the principle of operation, the heating elements are the same. A spiral acts as a heating element. But according to the execution of the heating elements, they differ and are divided into two types:

- Wet heating element consists of a spiral, hermetically sealed inside a copper tube. Quartz sand is used as a filler. It acts as an insulator and prevents the coil from touching the inner walls of the copper tube. The advantage of wet heating elements is low cost. The disadvantage is its large size and low electrical safety indicator. If the copper tube is damaged or the coil touches it, a breakdown occurs. As a result, a person using hot water receives an electric shock.

A storage water heater with a dry heating element is more expensive, but it is safer and has a long service life. Compact dimensions allow two heaters to be installed in the boiler. The most reliable is a dry heating element, the typesetting body of which is made of soapite.

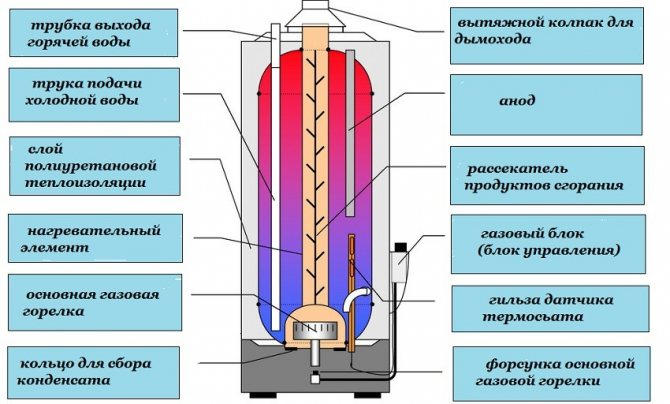

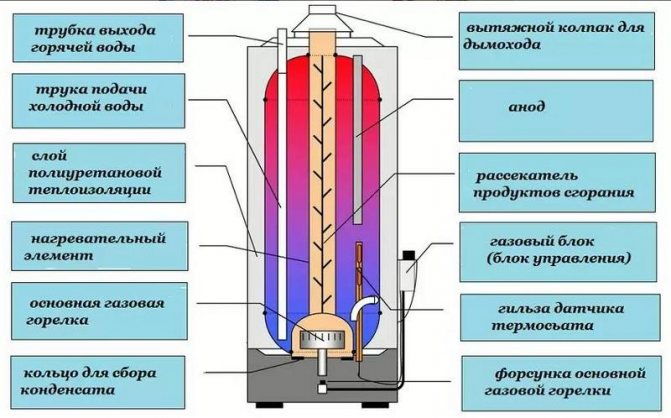

The device and principle of operation of a gas appliance for heating water

In terms of the structure and principle of operation, a gas boiler is slightly different from its electric counterpart. The same tank enclosed in a casing with polyurethane foam insulation is inherent in a gas water heater. The anode serves as protection. Cold water is supplied and hot water is drawn through the pipes mounted in the tank. The heating is switched on and off by a thermostat. This is where all the similarities end. Guided by the diagram, we will take a closer look at the boiler device in order to identify the main differences between the gas appliance:

- The main difference from an electric boiler is the presence of a gas device for heating water - a burner.

- The connection to the gas main is carried out through the block. A reducer is installed inside it, which is connected by a tube to the burner nozzle.

- The design of the storage water heater tank differs significantly from the electric analogue by the presence of a chimney. It consists of a steel pipe welded vertically through the entire tank. From above, the chimney is connected to an exhaust hood. Through it, the combustion products are discharged to the street.

- A splitter is installed inside the chimney. Its plates take away the heat of the exhaust gases and give it back to the water. It turns out double heating: from the burner and the divider.

- Due to the temperature difference between the cold water and the burner flame, condensation forms in the chimney. To collect it, a ring is installed under the burner.

A gas water heater works according to the same principle as an electric boiler. The only difference is that an electronic unit with a thermostat controls the operation of the burner. When the temperature drops, gas is supplied to the nozzle and ignition occurs. When the water temperature reaches the set parameters, the burner turns off.

Gas water heaters are in low demand due to the complexity of the installation. It will be necessary to draw up a project, and installation is allowed only by specialists of the gas service. However, the indisputable advantage is the savings due to the lower gas price.

Of the two options considered, the first place is given to electric storage water heaters. The device can be independently installed in any place. The main thing is to ensure an uninterrupted supply of cold water under pressure.

An electric storage-type water heater, or, in a simple way, a boiler, has long and firmly entered our life, providing additional comfort and allowing you not to depend on communal hot water supply systems. This simple device automatically maintains the required water temperature, while having a certain supply of it. The devices produced by the industry have a variety of shapes, sizes and external designs. Despite the apparent differences, at their core, all water heaters have a similar design and a single principle of operation. However, when making a choice between a particular boiler model, one should not only understand how it works, but also understand the features of the execution of some of its components.

Advantages and disadvantages of water heaters

Above, we talked about how an electric storage water heater works. Many of you may say that the cost of an 80L electric storage water heater is very high. But the price can be offset by its most important advantage - saving money. This happens if, when using a boiler, you simply do not pay for hot water. Moreover, this is of great relevance for those people who have meters installed in their house or apartment. In this case, only cold water and electricity are consumed. As for the latter, then in a minimum amount.

- Different models of water heaters can have different features. Horizontal flat storage water heaters of 80 liters have the following advantages:

- Compact dimensions. A flat boiler will take up several times less space than a round one. You can easily install it on the floor, on the wall in the kitchen, or anywhere else. The flat model of the heater is an excellent rhenium for an apartment with a small area.

- Maintaining the water temperature. In addition to all the advantages, the flat, round storage type heater has a Thermos function. This means that the cooling of the water is slow. This means that you do not need to heat up the water every time you need to wash the dishes or take a shower.

- For each water heater, the plant issues a two-year warranty. Proceeding from this, in the event of a breakdown, you have the right to contact the service center for repairs completely free of charge.

If we talk about the disadvantages of flat boilers, then, of course, much here will depend on the model. For example, if the heater is flow-through, then you can forget about saving electricity, since the water will be heated in the direction of its movement. This means that the energy for heating will be used as long as the water is flowing. Accumulative boilers in this case are much more profitable, so, for example, you can use heated water only once for a long time without turning off the heating element. Many developers specifically reduce the energy efficiency of flat types of heaters to reduce their overall size. Based on this, you do not need to buy a very small model, most likely, it will be ineffective.

What to look for when choosing a boiler

Each boiler has certain pros and cons. But there are several points that you just need to pay attention to when choosing all kinds of water heater options:

- Mechanical control of the device will always be more reliable than electrical control, since an electrician can damage the entire equipment in the event of accidental power surges.

- The enamel coating is the most effective as it can prevent corrosion at the weld. There is another great advantage of enamel - low electrical conductivity. As a result, the enamel lined tank will not corrode the seams.

- It is best to determine the volume of the water heater in advance, having approximately calculated how much water you intend to use per unit of time. A very small tank will not be able to meet your needs if you have a large family. But at the same time, a tank of 80 liters in a house for one person will consume a lot of unnecessary electricity.

- A heating element that will not be in direct contact with water will serve you much longer. This is due to the fact that scale does not begin to form on it. There is one more advantage of a dry heating element - not to drain the water from the tank.

- Any heating device requires constant maintenance, regardless of the frequency of its use. The more often you check the device for breakdowns and replace parts that are out of order, the longer the device will be able to serve you.

- If you buy a boiler from your hands, then you will not be issued a warranty card and you have big risks of buying low-quality equipment.

- The boiler must be installed by professionals. If you want to install a flat, vertical or other heater for 80 liters, then this can lead to its breakdown, and as for the warranty, it will no longer be valid.

It is worth noting that the devices of a barrel-shaped or flat boiler of the same volume will not differ from each other. So, when choosing its shape, you should be guided by the availability of free space in the house. An 80 liter flat vertical storage water heater will be a more suitable option for a small house or apartment.

Popular models and their characteristics

An 80 liter heater will be the best option for a family of two or three. The characteristics of boilers, their cost may vary. It depends on the manufacturer. Below in our article we will tell you about the most popular models. In addition to all of the above models, there are still a huge number of inexpensive and very reliable models of 80l boilers. In this case, the choice will depend on your own preferences in relation to one or another manufacturer and several factors. If you cannot choose the model you need on your own, then it is better to seek advice from an experienced specialist.

Boiler maintenance

If a boiler is installed, then you need to know how to care for it. To extend the service life of the water storage heater, you need to constantly carry out technical inspection and change parts. A very common problem is the formation of scale on the heating element. This can be completely avoided by installing special water filters on the inlet pipe, or by constantly replacing the heating element.

In addition, problems with the tank can twist if there are a large number of seams on it, which will be problem areas due to the formation of corrosion. This will be relevant for vertical, flat Termeks 80 liters boilers.

Boiler design

In fact, any water heater of this type is a large thermos with a tubular electric heater (TEN) inside, so the design of all boilers has the following elements:

- external casing with parts that allow the device to be mounted on a wall or floor;

- internal tank;

- a heat-insulating layer between the inner container and the body;

- tubular electric heater;

- thermostat with the ability to adjust the heating temperature;

- safety valve;

- protective magnesium anode;

- control and indication circuit.

When choosing a boiler, one cannot fail to notice a big difference in price, even between different models of the same manufacturer. It is primarily due to the technology and material used to manufacture the internal tank, as well as the presence of an electronic control and display unit.

These parameters determine the convenience of using the device, as well as the duration of its service.

Housing

Cases of water heaters have both strictly cylindrical and oval and even rectangular shapes, various colors and design designs. Often a thermometer is attached to the outside of the housing to monitor the operation of the device, as well as regulators or control elements. The housings are made of steel sheet or plastic.

Features of vertical and horizontal boilers

Inner tank

The design of the internal tank of the boiler must meet the criterion of increased corrosion resistance and at the same time withstand constant temperature changes, therefore, manufacturers pay a lot of attention to this element, developing new tank coatings and applying methods of its protection.

Steel tanks coated with glass enamel or glass porcelain

Such a coating is obtained by spraying a protective layer with its subsequent firing at a high temperature (up to 850 ° C). Glass enamel is not capable of oxidation, therefore it does not corrode at all. In addition, its smooth surface resists limescale build-up.

Paradoxically, the main disadvantage of such a coating stems from its advantage - the high hardness of the layer is low-plastic and over time, constant changes in water temperature lead to the formation of microcracks in its layer, which ultimately contribute to the destruction of the tank.

Manufacturers are constantly looking for new formulations for this type of coating. For example, the addition of titanium powder equalized the temperature coefficients of expansion of glass porcelain and steel, slightly improving the resistance of the layer to cracking. It is possible to slightly reduce the harmful effect of temperature exposure by setting the water temperature in the boiler to no higher than 70 ° C, although all the same, at least once a month, you will have to warm up the device as much as possible in order to comply with sanitary rules. Another disadvantage of the glass-porcelain coating of the tank can be considered the increased weight of the boiler. Companies producing water heaters with tanks of this type give a guarantee for their products for no more than 3 years.

Titanium coated steel tanks

By spraying titanium powder onto the inside of the tank, excellent corrosion resistance is achieved. At the same time, this type of coating has high strength and mechanical resistance, having weak points only at the welding joints. The warranty for a device with such a tank is up to 10 years, which is a huge advantage, even if you take into account its rather high cost.

Stainless steel inner tanks

Such containers are devoid of the disadvantages of the two previous elements. Stainless steel, like titanium, is able to withstand the effects of impurities in the water, as well as corrosion. It is believed that stainless steel gives water a peculiar smell and taste that appear during its heating, but this is just speculation, absolutely not confirmed by scientific research. It is known that "stainless steel" does not enter into a chemical reaction with water. Manufacturers also give up to 10 years warranty for such tanks, but they are the most expensive ones. Tanks made of stainless steel, as well as those with titanium spraying, are more susceptible to scale formation than glass porcelain, but this does not detract from their merits in the least. The inner tank contains pipes for supplying cold water and removing hot water, as well as an electronic heating and protection unit.

The principle of functioning of the units

Such units are accumulative and flowing. The water is heated in different ways. The former are also categorized according to the type of resources used. How does the boiler work? The operation of the devices is based on the principle of separation of water layers. They are heated to various levels. Warm ones, as you know, are located on top and enter the device through the hot water outlet pipe. Heaters are mounted at the bottom of the unit.It is in this segment that cold water enters. The presence of a device for scattering on the supply pipeline, which has a short length, excludes contact between the layers and prevents the liquid from pouring out in a stream. The thermostat monitors the temperature while the storage boiler is running. Heating of the liquid is carried out using heating elements (one or more). When the specified indicator is set, the EDS of the element is opened. The required water temperature is maintained due to good thermal insulation. A minimum of resources are spent on constant heating.

The water from above, which has left, is replaced by a new one supplied from the main. This is how the heating process is carried out, which is continuous. If the water flow is high, then over time, the outlet water temperature drops. Therefore, it is important to select a suitable container volume based on the amount of hot liquid intake. We have already written about "How to choose a water heater." How long it takes to heat up the water in the boiler depends on the volume, power of the device and the set temperature. For example, if the indicator is up to 85 ° C, then it will take 2 hours. It is irrational to heat water below 60 ° C. Colonies of bacteria can form in it. The cold water supply to the unit is always open, when heating is carried out, steam bubbles form. After that, air accumulates above the liquid mirror. He tries to push the water out of the device. Where does the air go when filling the boiler as a result? Due to the low pressure level in the cold pipe, no liquid is pushed out. As a result, the mirror goes down below the fence. When the tap opens, then first comes the air, and only then the water.

Heating and protection unit

The elements responsible for heating water to a certain temperature, as well as protecting the metal of the inner tank from destruction, are installed on a metal flange, which is connected by means of a seal to the inner tank of the device.

An example of a control unit

Heating elements of various capacities are used to heat water. Depending on the heating principle, a distinction is made between:

- "Wet" heating elements, which are in direct contact with water, therefore inevitably become covered with scale, which must be periodically removed, otherwise the heating element will fail due to overheating;

- dry type heaters. They are free from this drawback, since they are installed in a metal tube, which makes contact with the liquid. This scheme allows you to get rid of scale not only on the heater, but also on the tube covered with a layer of glass porcelain.

Some boiler models are equipped with several heaters. This design allows for stepwise regulation of heating, and also reduces the number of switching cycles for each of them (voltage surges during switching on of devices affect their durability).

Together with heating elements, a thermostat and a magnesium rod (anode) are installed on the flange. The thermostat is responsible for turning on the heating element when the water temperature drops below the set by the consumer. Thermoregulators of both mechanical type and electronic devices operating in conjunction with an electronic control unit are used. Often, the thermostat device includes a safety shutdown circuit for the heating element in the absence of water in the tank. The magnesium electrode is designed to reduce the exchange of ions of metal components inside the boiler, giving up its own particles in return. Such a scheme reduces the effect of elution of electrons from structural elements and they corrode to a much lesser extent. At the same time, the magnesium rod itself collapses rather quickly and requires periodic replacement (when thinning to 10 mm or reducing the length to 200 mm). The control and indication circuit provides additional convenience when using the water heater, having the functions of precise adjustment of the water temperature, switching on heating by time, maintaining a different degree of heating depending on the time of day.

How to properly use an already operating water heater?

Example 3 of connecting an electric water heater.

You should be aware that the boiler must not be disconnected from the electric current during operation. If hot water is temporarily not needed, then the device can be turned off from the outlet. This will save you energy.

However, many experts claim that if the boiler is constantly filled with heated water, then it does not undergo destruction (corrosion). In addition, it is much easier for the device to set the required temperature than to start heating from zero. To prevent a fire hazard, be sure to ensure that the appliance is grounded.

Flow-through boilers have no restrictions on the amount of heated water. Usually they are used at the same time only in one place (where they wash the dishes or take a bath). If you open the tap completely, the water in the water heater will not have time to heat up. In order to reduce heat losses, the boiler should be installed as close as possible to the place where hot water is used.

Related article: How to sheathe a door with clapboard: recommendations, material advantages

If hard water is supplied to the house, then it is necessary to install a water purifier, because otherwise the water heater will fail very quickly. If the device is installed in a sauna or bath, then you need to ensure that no drops of liquid fall on it. It is impossible to use a flow-through electric boiler in those houses where the air temperature often drops to zero.