Regardless of whether the balcony is actively used for personal needs or is intended only for storage, the room is constantly under the active influence of the environment. In particular, if there is no glazing. The choice of styling material is an important step. The overall result of the equipment of the place depends on it.

Now on the building materials market there are many coating options that have different properties. Some of them are suitable only for closed spaces, others can be adapted to more difficult operating conditions. The list of the latter includes linoleum.

Varieties of linoleum and the best choice for a balcony

Today, there are many varieties of linoleum on the market, which have some differences in their chemical formula, however, other performance characteristics are quite similar. The main types and varieties of modern types of linoleum include:

- Made from natural ingredients. This type of flooring can be safely laid in a children's room without fear of its effect on the child's health, but it is poorly suited for a balcony or loggia;

- Manufactured on the basis of rubber;

- Colloxylin;

- Glyphtal;

- Made on the basis of PVC.

How to lay linoleum on the balcony with your own hands

Before laying linoleum, you should take care of the flat surface of the base for this material. If the base is a concrete screed, then in this case it is possible to perform high-quality priming of the surface with special soils, which will ensure high adhesion and strength of the base. In the case of laying linoleum for a balcony on a wooden floor, it is necessary to pre-sheathe its base with plywood or chipboard, which will form a flat mounting platform, where later you can lay linoleum.

In order to efficiently and quickly lay linoleum on the balcony, you need to take care of the availability of the following tools at hand:

- Construction or stationery knife (today in specialized stores you can find special knives for linoleum on sale);

- Roulette or rule with a measuring scale;

- Roller for applying a primer on the surface of the base;

- Construction marker;

- Paint brush or spatula;

- Impact drill or hammer drill.

At the first stage of work, the old floor covering should be dismantled. After that, debris and dust are removed from the surface of the base.

At the next stage, priming is carried out with special solutions of the working surface, for which a roller is used. If the base is uneven and there are significant deformation areas, it is necessary to equip an additional cement screed, after which the base surface must also be primed. Most primers provide for an average time of complete drying from 1 to 2 days, it is after this time that linoleum can be laid.

The required section of the coating is cut off with a construction knife. Also for this operation, metal scissors can be used, which perfectly cope with the task at hand. The side of the linoleum that will be laid on the base must be clean and non-greasy.

The working surface of the base is carefully processed with a paint brush or spatula with construction glue.A previously prepared piece of floor covering is applied from above and pressed against the base. For a reliable connection of linoleum to the base, you can take care of the presence of any load, however, it should be borne in mind that pressure should be applied to the entire floor area relatively evenly.

Linoleum on the balcony is ready for use after 3-4 days, during which the glue dries completely, however, this period may vary depending on the brand and manufacturer.

Laying linoleum with your own hands does not present any difficulties, however, special attention should be paid to accurate calculations and comparison of the cut-out section of the coating with the perimeter of the balcony or loggia. The final stage of laying linoleum should be considered the installation of baseboards around the perimeter of the room

To do this, a mounting plate is attached to the anchor using a perforator or a hammer drill on the balcony walls, on which the decorative plinth itself is subsequently applied

The final stage in laying linoleum should be considered the installation of baseboards around the perimeter of the room. To do this, a mounting plate is attached to the anchor using a perforator or a hammer drill on the balcony walls, on which the decorative plinth itself is subsequently applied.

If the floor gets wet: consequences and solution

Excessive moisture can adversely affect the structure and condition of the material. When the canvas gets wet, it is recommended to temporarily remove it from the floor, lay it out in another room so that the front side looks down. It is permissible to reuse rolls only when completely dry.

Facing on a soft basis of the cheap price segment will hardly be able to be “resurrected”. The felt included in the composition will not allow the material to dry completely without additional damage, in particular, in the form of a musty odor and mold.

When you remove the canvas, check the condition of the backing:

- whether the base is deformed - the floor may become wavy;

- whether the basic requirements for the canvas have been preserved - dryness, evenness, strength.

It is quite simple to check the base for moisture. You will need one-piece dense polyethylene (there should not be any damage in the form of holes) meter by meter and wide adhesive tape. Glue the resin all over the room to the floor and let it sit overnight.

In the morning, a check is carried out: if an accumulation of liquid appears on the inner surface, it is necessary to leave the base to dry. Do not put the rolls back immediately.

When the surface gets wet, it is important to protect it from the possible appearance of mold in the future. Treat with antifungal drugs.

Installation of infrared film floor

The infrared floor is designed like a film in which infrared elements are embedded. When connected to a network, they emit rays of a certain spectrum. A person feels this as warmth. The film coating heats the linoleum, and through it the room in which it is installed.

The infrared heater does not require a screed filling step. This greatly simplifies the installation of equipment. Often, the installation is done with your own hands, without contacting specialists.

Features of laying a film heater:

- practically does not change the original floor height;

- when laying under linoleum, a hard layer of plywood or fiberboard sheets should be provided;

- experts consider it acceptable to have a rough floor drop of up to 1 cm per meter of length;

- an infrared heater creates optimal heat output for linoleum;

- has increased fire safety;

- can be integrated into the “smart home” system;

- easy dismantling.

It is not necessary to fill the screed when installing an infrared floor heating

The thickness of the linoleum should not interfere with the spread of heat and at the same time should not be too small. In the latter case, irregularities, floor differences will be visible.

The structure of the floor relative to the room can be made according to an individual scheme. The structure of the material allows for the installation of local areas. If necessary, the heating element can be mounted in a different place.

Sequence of stages:

- preparation of a concrete base;

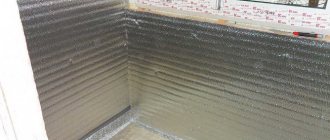

- laying of heat-insulating material;

- fixing the thermostat on the wall, connecting it with a power cable and wires for temperature sensors;

- fixation of thermal sensors;

- cutting out the film;

- unfolding on the floor surface and connecting wires;

- test connection;

- a layer of protective plastic film;

- a layer of plywood or fiberboard;

- retesting the system;

- laying linoleum.

For thermal insulation, a roll of foamed polyethylene material is used. It is resistant to moisture, is not affected by fungus, mold. Excellent waterproofing is an important advantage. The material is laid on the floor tightly, without gaps, the overlap technology is not used. The thickness must be at least 5 mm.

Linoleum in the case of an infrared warm floor is laid on a layer of plywood or fiberboard

The thermal sensor is attached to a carbon thermocouple. The structure itself and the wires extending from it are "recessed" in an insulating material. Otherwise, the floor surface will be uneven in these places.

The film is laid strictly according to a previously prepared scheme. Places where stationary furniture or household equipment is installed are not insulated. Lack of aeration can lead to overheating of the flooring material. The distance from the main heating source must be taken into account - it must be at least 30 cm.

An important point is the connection of the infrared system and the power source. For this purpose, special rivets are used. Fastening is carried out with a tool designed for this.

The correct procedure for connecting an infrared heated floor is important. Despite the apparent simplicity of work, it is better to entrust the connection of the heating element to the thermostat and the power source to a professional electrician. You can divide the responsibilities - carry out the preparatory work and laying the flooring yourself, and entrust the installation and connection of the film itself to an experienced specialist.

Features of using linoleum with an infrared warm floor

Successful examples and options

For modern balconies, homogeneous linoleum is best suited, which is not afraid of frost or heat, has an increased level of wear resistance and retains its shape even under serious mechanical stress.

Relinum can be used to cover the floor in rooms without heating and in many other areas with severe temperature fluctuations. With the help of this product, you can equip a garage with high quality.

All rights reserved, 14+

Use of any material without our prior written consent is prohibited.

Surface preparation

Floor screed and cleaning

Regardless of which type of underfloor heating is chosen, for its installation it is necessary to prepare a reliable base that meets safety requirements.

The concrete base is processed in the following sequence:

- Removal of old finishes and remaining debris. Dismantling of communications.

- Checking the surface condition. If there are gaps and holes, they must be repaired. The protruding fragments are grinded or cut off. If the slab is too loose, it should be leveled with a light plaster mortar.

- Base treatment with a deep penetration primer. To achieve the best effect, you need to do this twice.

- Application of a waterproofing layer. At the choice of the master, film or coating materials are used.

- Insulation laying. Depending on the characteristics of the room, polystyrene, penofol or penoplex are used.

- Covering the material with insulating material (roofing material, polyethylene).

Installation of underfloor heating in a wooden house

The wooden floor is prepared according to the following method:

- Removal of finishing. If you plan to reuse it, you need to do it carefully and carefully.

- Inspection of wood for rot, fungus and mechanical damage. Carrying out repairs in the required volume.

- Floor treatment with antiseptic and fire retardant. Application of liquid impregnation.

- Arrangement of waterproofing using strips of waterproof material.

- Laying and fixing the membrane with staples to remove moisture.

- Insulation placement. For wood, it is better to use perforated foam on aluminum foil.

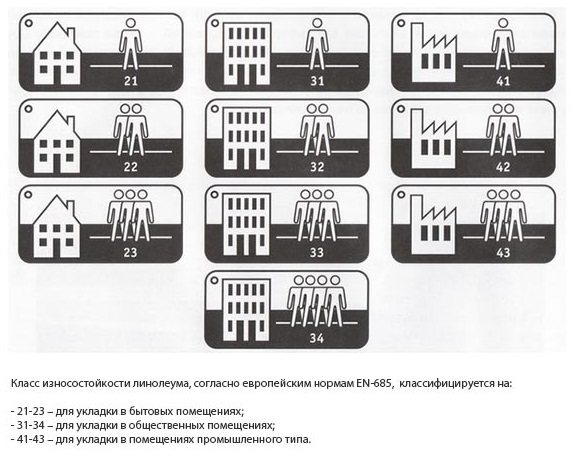

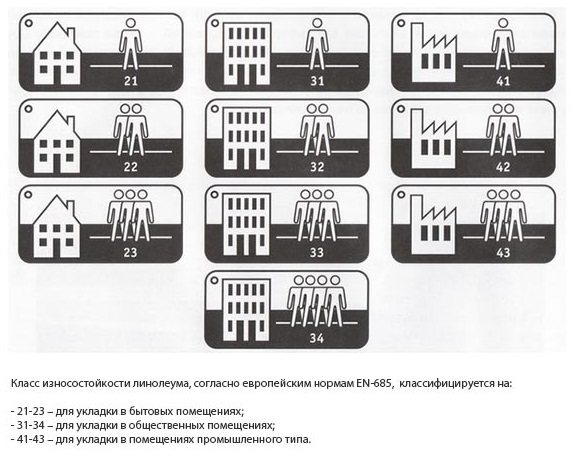

Wear resistance class

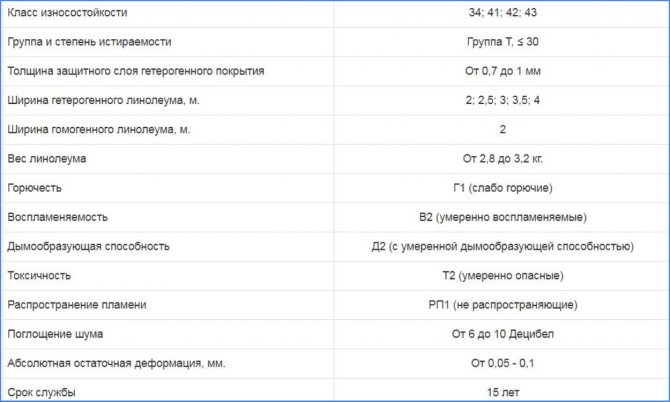

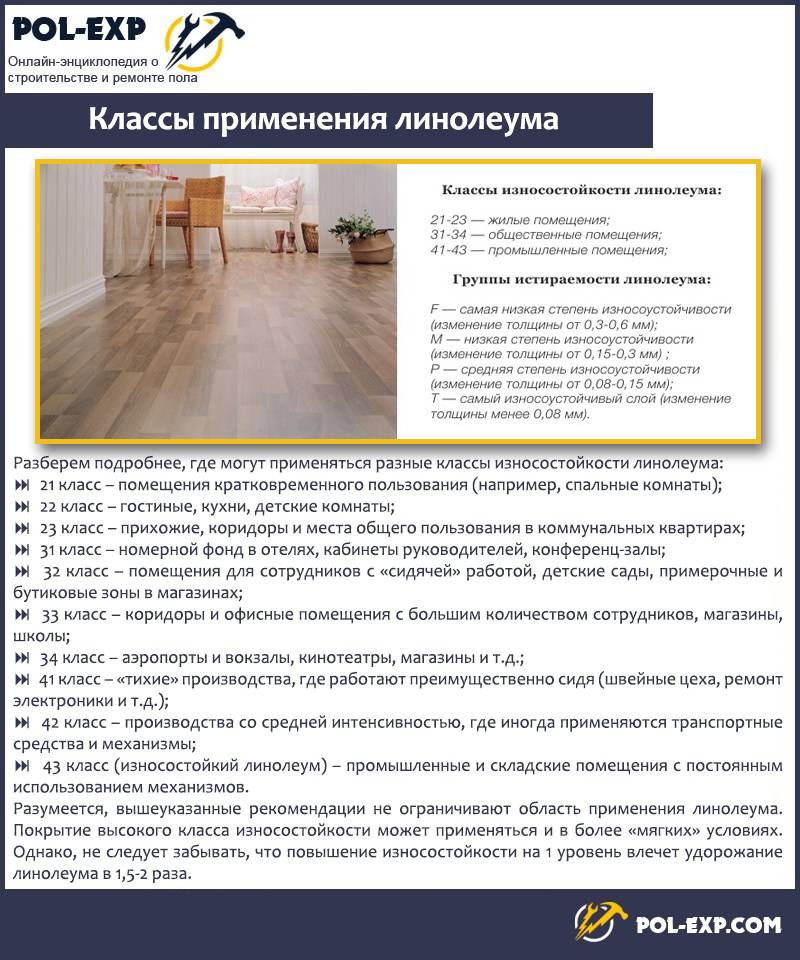

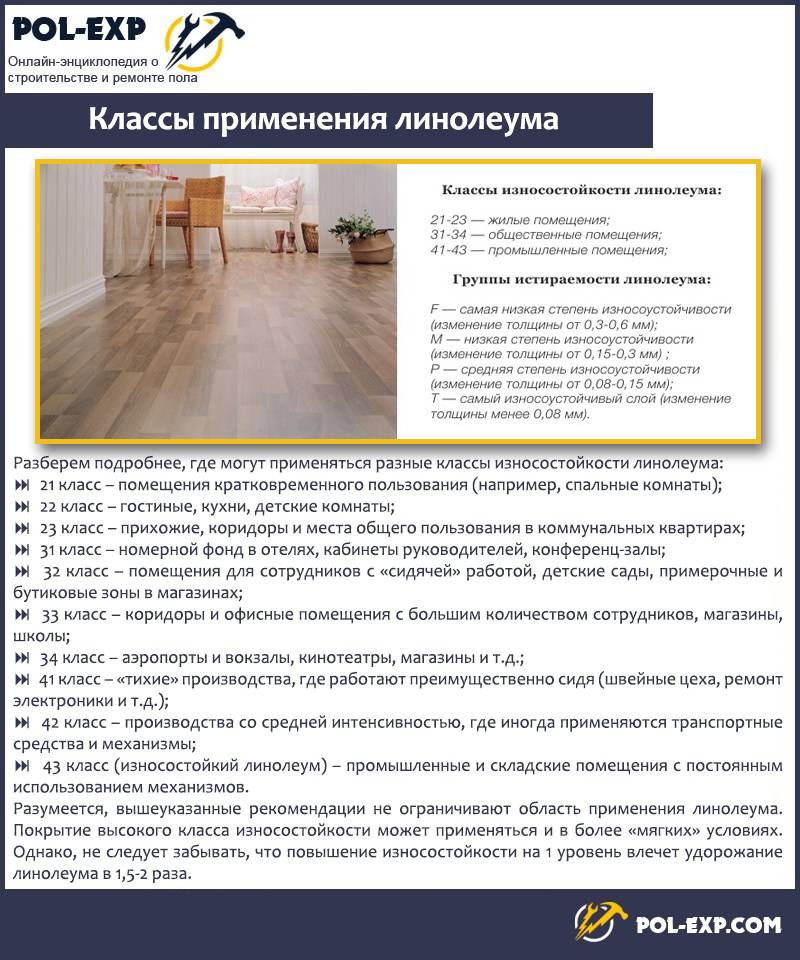

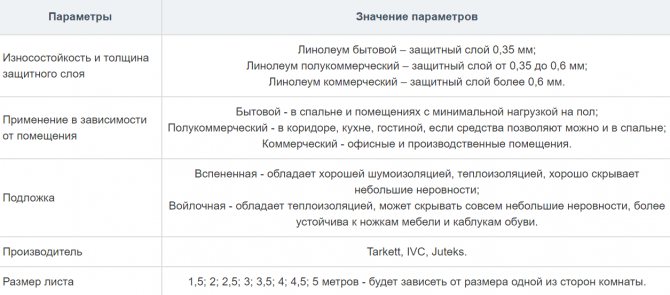

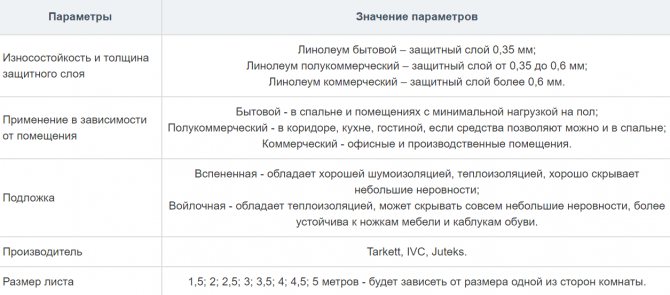

Depending on the load that linoleum can withstand (the intensity and number of people moving along the surface of the floor covering), it is divided into wear resistance classes.

A unified classification system for floor coverings, unites any materials intended for this purpose (linoleum, parquet board, laminate). Thus, you can compare two completely different coatings, and determine which one is able to last longer under a given load.

The wear resistance class is marked with two numbers. The first number denotes which room this coating is intended for. The second number indicates the degree of load for which this material is designed.

Explanation of wear resistance marking by type of room (first digit):

- 2 - premises for personal use (apartments, summer cottages).

- 3 - offices and other commercial organizations.

- 4- industrial premises (workshops, workshops, laboratories, etc.).

Explanation of wear resistance marking (second digit):

- 1 - only very low load is allowed.

- 2 - linoleum can be influenced with an average load.

- 3 - the material is designed for high load operation.

- 4 - the maximum possible load capacity of this coating.

Types of linoleum

To understand which linoleum to choose for your home, you must first find out what types of linoleum exist. Today we offer a wide variety of linoleums made from natural as well as synthetic materials. Natural or polyvinyl chloride, glyphthalic, colloxylin, rubber - this is an incomplete list of the types of this floor covering available to the modern consumer. Having familiarized yourself with the advantages and disadvantages of each of them, you can answer your own question: which linoleum to choose for an apartment.

Natural linoleum is composed of wood flour, linseed oil, cork flour, pine resin, natural dyes and limestone powder, and its base is jute fabric. Since this coating is made from natural materials, it is perfect for rooms where people with asthmatic or allergic diseases live, as well as for children's rooms.

Natural linoleum does not change its color and structure over time

Its advantages: • resistant to abrasion; • environmentally friendly material; • does not fade in the sun, does not change its structure and color over time; • possesses bactericidal properties; • does not support combustion (a burning cigarette falling on it will not leave a trace on the coating); • easy to clean; • it can be of various colors (usually with a "marble" pattern or monochromatic). Its disadvantages: • certain fragility (you cannot bend it, cracks may appear, during transportation and work with it you cannot throw it); • the use of the coating in rooms with high humidity (toilets, bathrooms) is undesirable; • rather high cost.

PVC linoleum is made on a fabric or non-woven thermal insulation base. Such a coating can be single-layer or multi-layer. Domestic manufacturers make it using European technology and the price of their products is available to almost everyone.

PVC linoleum made using European technology

Advantages: • low thermal conductivity; • pronounced dielectric properties; • environmental Safety; • not subject to decay; • wide palette of patterns, patterns and shades; • simple styling technology. Disadvantages: • sensitive to high temperatures; • not resistant to chemical solvents, fats and alkalis; • when the temperature drops, its elasticity decreases sharply, it can crack.

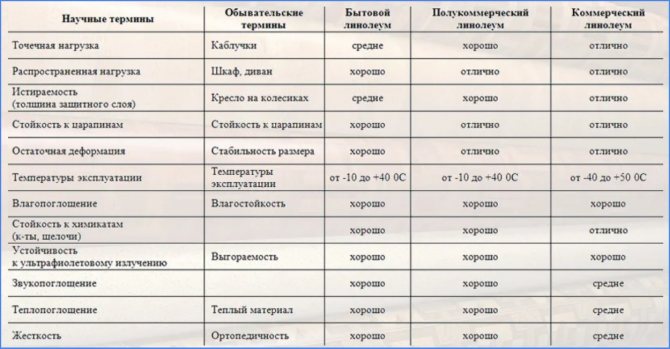

Synthetic linoleum is divided into: • commercial; • semi-commercial; • household. Household (for home) thinner, cheaper, less durable (service life - no more than 3-5 years). Commercial linoleum (for office and work premises) has the highest wear resistance, it is the most durable and thick, can last more than 20 years Semi-commercial linoleum occupies a middle position between the first and second types, it is used either in commercial premises with low traffic, or in the premises of a house or apartment with the highest traffic. Its warranty period is 7-20 years. There are many different subspecies of PVC linoleum - conductive, noise-absorbing, antistatic.

This type of linoleum is made by applying an alkyd resin to a fabric base. Advantages: increased sound and heat insulation qualities. Disadvantages: fragility and, as a result, the complexity of laying, a tendency to cracks and fractures. Before laying, this type of linoleum must be kept in a warm room, otherwise its deformation is possible: the length decreases and the width increases.

The basis for this type of linoleum is nitrocellulose. Produced usually baseless. Advantages: moisture resistant, elastic, fireproof, has a decorative shine. Disadvantages: prone to shrinkage, rather sensitive to temperature changes.

This linoleum is two-layer. Its backing layer is made from old crushed rubber with bitumen. The top layer (front) is made by mixing rubber, pigment and filler. Advantages: high elasticity and moisture resistance. Disadvantages: it contains gradually volatilizing substances harmful to humans, so it is not recommended to lay it in living rooms.

Advantages and disadvantages of linoleum flooring

Before choosing a floor covering, you should carefully analyze all its pros and cons.

The positive qualities of linoleum flooring:

- Large selection of various colors, shades and patterns. A large selection of linoleum flooring eliminates the need to think about the combination of wall and floor colors on the balcony. You can sheathe the balcony with any material, and then easily match the linoleum in the color and pattern of the walls.

- Ease of installation. Of all types of existing flooring, linoleum is perhaps the most convenient material for installation. Any person is capable of measuring and laying it without the help of specialists.

- Heat, vibration and noise insulation. Due to its viscous structure, linoleum flooring perfectly absorbs sound waves coming from both the apartment and the street. Floor coverings made with a base serve as a very good heat insulator, preventing the flow of cold from the outside to the balcony. Having laid linoleum, you can save yourself from the need to produce additional thermal insulation of the balcony floor.

- Ease of use. The advantage of linoleum over other types of flooring is that it is easy to clean. It is resistant to chemical cleaning agents, does not wet or absorb moisture, and does not slip underfoot.

Tile

The advantages of the tiles are obvious:

- high decorativeness;

- long service life;

- strength;

- frost resistance;

- resistance to chemicals;

- environmental friendliness;

- absolute incombustibility.

Balcony tiles

It is easy to care for it, although styling requires a certain skill, it is not particularly difficult. All this makes the tile almost ideal for balcony flooring. To reduce the load on the ceilings, lightweight tiles are produced, and for open balconies there are many options with a rough anti-slip surface.

Balcony floor tiles

Disadvantages:

- tiled floors are cold to the touch, therefore, on closed balconies, it is recommended to lay them on top of floor heating systems;

- the surface of the tile has a very low sound insulation, and when walking, there are booming sounds from steps.

The assortment of floor tiles is unusually wide, the models differ in the manufacturing method, decorativeness, size, presence or absence of glaze.

Ceramic or tiled

Tile

This type of tile is considered the most common. It consists of a mixture of sand, clay and modifying additives, pressed and fired at a high temperature. After cooling down, a decorative glaze coating is applied to the surface of the tiles, giving the tiles such aesthetic appeal.

Porcelain stoneware

Laying porcelain stoneware on the balcony

In the manufacture of porcelain stoneware, the working mixture is fired at higher temperatures than the tile, therefore the finished material has an external resemblance to natural stone, has the same technical characteristics in terms of frost resistance, strength, durability. Porcelain stoneware is produced both in pure form and with a glazed coating, it looks very decorative, but is a rather expensive material.

Clinker tiles

Clinker tiles

This type of tile is distinguished by its durability, very high wear resistance, it is not afraid of moisture and negative temperatures. For an open balcony, such a coating is ideal, moreover, the cost of clinker tiles is lower than porcelain stoneware.

There are several other types of tiles, among which Cotto and quartz vinyl tiles are worthy of attention; each variety has its own peculiarity. To make such a coating look the most impressive, observe several important rules when choosing.

Clinker tiles Feldhaus klinker, Stroeher

Large tiles visually reduce the balcony, therefore, the smaller the area, the smaller the tile should be. For balconies of a standard area, experts recommend choosing tiles of 40x40 cm.The dark color also visually reduces the room, and bright and light shades make it more spacious

This is especially important for balconies located on the north side, where there is too little light. For a glazed and insulated balcony, you should purchase tiles with a wear resistance class of PEI 3. The higher the indicator, the more massive and heavier the material. The tile should be bought at one time, and with a small margin - about 5-7%

The tiles from the second batch may differ slightly in color, and if you suddenly have to buy additional material, the coating will be heterogeneous.

What are the alternatives

Not all of the floor coverings on the modern market are suitable for a balcony. Many of them will not tolerate such almost street conditions - changes in temperature and high humidity. Having chosen in a hurry the unsuitable coating, which quickly fell into disrepair, some owners simply cover the concrete floor surface on the balcony with weather-resistant paint. Yes, she will endure bad weather and will last a long time. But neither warmth, nor comfort, nor even more an aesthetic look should be expected from her. Plus, all this creativity looks to put it mildly depressingly.

There are more modern and attractive materials that can be used on the balcony. Let's consider them in comparison with the possibilities of linoleum.

Laminate

It is durable, environmentally friendly and, which is very important, withstands temperature fluctuations.Easy to install and relatively inexpensive. But it has one significant drawback - it is afraid of moisture. At high humidity, it will quickly deteriorate.

Tile

It will delight you with strength, frost resistance (if you choose the right type) and, possibly, beauty. But in this case, you should not count on a warm floor and ease of installation. And to go to the balcony in winter, you will have to wear boots. To avoid cracks due to water entering the pores of the tile and freezing it at low temperatures, it is better to give preference to porcelain stoneware.

Self-leveling floor

Serves for a very long time. This liquid coating is resistant to temperature changes and does not allow moisture to pass through. But aesthetics does not belong to the list of its merits. It is rarely used in residential premises.

Wooden floor

Suitable only for balconies and loggias that are fully glazed and protected from rain and snow. Needs increased waterproofing. You will definitely have to treat each board with anti-fungal and anti-rotting agents.

Carpet

It makes sense to use it only if the balcony is completely closed and well insulated. For example, if the balcony is planned to be converted into a study. Soft, effective and pleasant to the touch, the carpet will allow you to walk on the balcony even with bare feet. But he is, of course, far from the durability and strength of linoleum.

How can you insulate

A high-quality floor installation using the correct backing material will extend the life of the base. Even if the floor covering wears out over time, the substrate can last many times longer than linoleum, and if the technology of preparation and installation is observed, it will exclude the alteration of the base: it will be enough to simply remove the old linoleum and replace it with a new one.

Installation technology is not as complicated as it seems at first glance.

It consists of several stages:

- Work surface preparation;

- Vapor barrier laying;

- Substrate flooring;

- Adhesive fixation.

Preparation

The first step is to level the floor. First, it is cleaned of construction dust, debris, then leveled with a screed. If the irregularities are insignificant, you can cover cracks and pits with a cement mixture. Tile adhesive of the Ceresit and Unis brands is well suited for this.

Before masking defects, it is important to prime the floor surface in these places. It is important that the surface is clean, dust-free, grease-free

There should be no bumps, height differences on it. If the base is made of plywood, a layer of waterproofing is placed on the concrete floor. This is important for the wood to be protected from moisture: this increases the service life of the material.

Waterproofing

Before laying the substrate, you need to check the floor surface several times for fumes by applying a plastic wrap to the floor (if there is moisture, it will be visible). If a technology with a vapor barrier is conceived, ordinary plastic wrap can be used as it, placing it in strips with overlaps of about 10 cm (2 cm is enough for walls).

It is preferable if the waterproofing is a single sheet of film. This stage is carried out without fixing to the floor: subsequent layers will prevent the film from shifting. You can fix the film between each other (any, even packing tape is suitable, but the best is durable reinforced).

Substrate

After that, you can lay the substrate. This must be done carefully, no gaps are needed: the material is applied with strips end-to-end, fixing the insulation between each other with double-sided tape. The required amount of material is calculated in advance: there is no point in overpaying for excess raw materials that must be trimmed. When laying out the material, it must be straightened immediately: folds and waves, and even more so distortions, are unacceptable on the surface.

The formation of joints is unacceptable for the reason that the floor covering will give out this relief, regardless of the class and type of canvas. This is especially true of the commercial type, which has a minimum thickness of 2-3 mm. If the substrate is dense, even a household coating will eventually show the curvature of the interlayer runs. Corrugated synthetic material should be laid with the relief facing down (towards the concrete).

Fixation

The substrate must be glued to the floor, otherwise it is impossible to glue the linoleum itself. Fixation is carried out using a special glue on a resinous, polyurethane base or tape (depending on the type of substrate)

It is important that the glue is suitable for a specific material, otherwise installation defects are not excluded. When working with double-sided tape, first it is glued to the concrete at the joints of the joints

After the canvas is laid and straightened, the top layer is removed from the tape, and the substrate is glued to the floor. After the substrate, it remains to lay the linoleum, cutting it off at the location and gluing it to the floor with the substrate using mastic.

The technology of floor insulation on boards is appropriate if there is no humidity in the room.

Output

Having arranged a balcony in this way, it can be used for gatherings and tea parties, a small greenhouse and even a study. Using linoleum on the balcony as a floor covering, pre-warming and making minor repairs, the balcony can be used more efficiently than just for "smoke", "go out to get some fresh air" or "hide old things that are a pity to throw away."

Articles on finishing balconies and loggias with popular finishing materials:

An additional room in the dwelling is never superfluous. And linoleum will help turn the balcony into a cozy living area. Tastefully selected and laid out in compliance with these rules, linoleum will decorate your balcony. But the main thing is that it will protect it from cold, moisture and other weather troubles for many years.

If you liked this article, then please vote for it by clicking on one of the social buttons below or leave your comment on it.

We find the rest of the publications and carefully read them in the map section.

Do not miss the release of other new, useful and interesting articles with nuances on the topic of repair and arrangement, subscribe to the update. Good luck to all!

Hello dear blog readers prosamostroi.ru! For more than a hundred years, linoleum has remained the most affordable and widespread floor covering. Manufacturers offer material of various widths, without a base and with various bases that serve for insulation and impart strength, as well as three categories of resistance to abrasion and tear, dividing linoleum into a household class, as well as commercial and semi-commercial. For example, we considered a very interesting specimen of linoleum in the article - polyvinyl chloride linoleum on a heat-insulating base. Have you heard of this !? If not, I advise you to read it. The flooring market today offers a huge collection of linoleum of different textures, patterns, colors and thicknesses. Any consumer has the opportunity to choose a material with the best performance and aesthetic parameters at an affordable price. Laying linoleum on a concrete base has its own specifics, therefore, the correct selection of material and a clear understanding are required, how to lay linoleum on a concrete floor.

Features of linoleum for a balcony

The use of such coatings requires certain characteristics of the material, among which the most important are the following:

- frost resistance, allowing you to maintain strength in the most severe frosts;

- fire safety (so that an accidentally flown cigarette butt does not cause a fire on the floor covering);

- elasticity, excluding cracking at strong temperature changes;

- wear resistance for a long service life;

- non-slip surface (very often the balcony is flooded with water, which makes it very dangerous for a person to be on a slippery surface);

- resistance to prolonged exposure to sunlight.

In the assortment of many manufacturers there are the most frost-resistant coating options that are best suited for arranging an open balcony or loggia. Not always the most expensive material will have the required combination of qualities, respectively, before purchasing linoleum for a loggia, ask the seller what specific qualities your chosen product has. Be sure to require documents confirming the presence of the declared characteristics.

What and in which case to choose

You can choose between linoleum and laminate as a floor covering only in one case: when it comes to a glazed balcony or loggia. Open space implies the use of other materials (such as tiles). In extreme cases, linoleum can also be put on a balcony without a double-glazed window, but under the influence of temperature and moisture changes, it will quickly begin to rot from below.

If you have a glazed or insulated loggia, you can choose what you like best. One way or another, it is necessary to level the floor or install a wooden flooring, on which the covering will already be laid.

Laminate is more durable, looks better and gives a greater guarantee that there will be no traces of furniture on it. However, very few people can afford to prepare the floor and lay the coating on their own. This is not the most economical option.

Linoleum is inexpensive and quick to fit (and you can do it yourself). The choice of colors is much wider than that of the laminate. However, if you decide to put furniture on the balcony or loggia, especially heavy furniture, be prepared that it will leave noticeable marks or even break through the covering.

So if you don't plan to spend a lot of time on the balcony, and of all the furniture there will be only a table and a couple of chairs, you can put linoleum on the floor. In all other cases, experts recommend opting for a laminate.

What kind of linoleum is used to equip wooden floors

Any type of linoleum is distinguished from other materials used for finishing by the following positive characteristics. This type of coating is quite strong, has a long durable service life, is not capricious in care, is not afraid of water and has a reasonable price with a wide variety of colors and textures. And there are quite a few types of linoleum, among them it is easy to choose the type of coating that will be optimal in terms of price and quality.

Linoleum on wood floor

Table. The main types of linoleum.

| View | Characteristic |

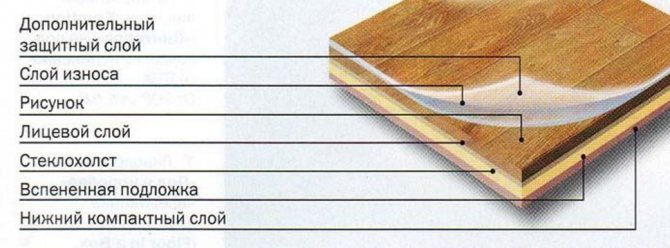

| PVC linoleum | For the manufacture of this type of coating, an artificially created polymer is used. The material can have several layers, a different base, or not at all. The thickest version of such linoleum usually has a foam base and consists of four layers. Its thickness is at least 4 mm. The bottom layer is made of foamed vinyl, followed by a reinforcing fiberglass layer. The PVC layer sets the selected color of the material, and also protects the material from negative external influences. This material is characterized by increased heat and sound insulation characteristics. |

| Rubber | This linoleum is called "relin". It is a multilayer material with a thickness of about 3 mm. It is made on the basis of bitumen, crushed rubber or rubber. The upper part is represented by thin colored rubber. The material is elastic, not afraid of water. |

| Alkyd | This type of coating can have a thickness of 2 to 5 mm. For manufacturing, special pigments, fillers and alkyd resins are used. The material is resistant to abrasion, can have different colors, and is distinguished by excellent sound and heat insulation performance.But in general, it is a rather fragile species that can be easily damaged at a break. |

| Colloxylin | Material that has no base. Nitrocellulose is used in the production process. The coating is characterized by a high degree of resistance to moisture, does not burn, and is very elastic. |

Glyph (alkyd) linoleums

Examples of rubber linoleum (relin)

Laying linoleum on a wooden floor

Examples of natural linoleum

Of course, linoleum made from PVC is most often used. Compared with other types, it has a relatively low cost, but at the same time it is distinguished by high quality indicators.

Different types of polyvinyl chloride linoleum (PVC)

Any type of linoleum can be laid on wooden floors. Still, it is recommended to take material with sufficient thickness. If you look at the classification of linoleum, then it is recommended to purchase a semi-commercial option for home use.

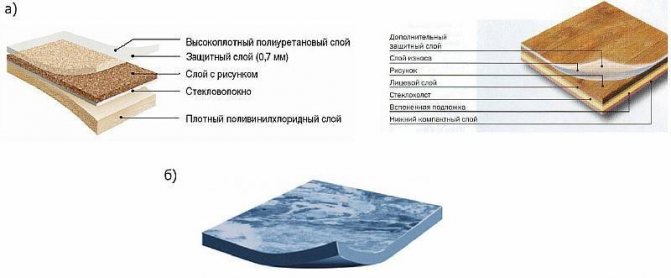

The structure of household polyvinyl chloride linoleum (PVC): a) multilayer; b) single layer

When choosing a material, it is important to take into account the conditions of its operation. For example, in rooms with high traffic in residential buildings, only a semi-commercial option fits - household items here will quickly lose their appearance

But in the bedroom or nursery, the first one can be the best solution, especially if you want to save money. In any case, it is not recommended to buy a coating less than 3 mm thick.

Commercial linoleum

Classes of application of linoleum

Table of the main criteria for choosing linoleum

Laying on the floor

When laying on the floor, a frost-resistant coating is usually rolled out or immediately glued to the base with a special glue with frost-resistant properties, and they often do it with their own hands, without the help of specialists.

To lay linoleum with high quality, first prepare the basis for this material. The concrete base is best covered with a layer of special plywood that has moisture resistant properties. It will play the role of an insulating base for linoleum. If a warm floor is installed, then a special screed with electrical elements is applied to the base.

For high-quality thermal insulation of floors on which you want to lay linoleum, you can use Penoplex - an excellent new generation material with high heat-saving characteristics. This environmentally friendly material is not subject to decay, it is convenient to work with it under all kinds of climatic conditions without protection from various precipitation.

Many ordinary people ask the question, is it possible to lay linoleum on a wooden surface? This is especially worrisome for the owners of wooden dachas, which are rarely heated. In fact, there is no fundamental difference in what the surface will be made of, on which you want to put the frost-resistant material. The main requirement that must be strictly observed is a flat floor surface.

The material is rolled out on the floor, leaving it in the room or on the balcony in such an expanded form so that it “acclimatizes” for about a day. During this time, the product gains temperature. The installation of the product is completed by installing soft skirting boards.

Infrared floor or water equivalent

The difference between these types of heating systems lies in the coolant. For example, an infrared warm floor under linoleum or other decorative coating consists of a polymer film and plates of a special material embedded in it.

This option is a type of electrical system. The film is connected to a power source. It needs to be laid on a rough base.

Given the simple installation process, it is quite possible to do all the work with your own hands. Heated film is better than other options also because of the minimum thickness, as well as due to intense heating at low power.

The water floor is heated by the central heating system of the building.

Hot water acts as a heat carrier.This option is laid in the thickness of the concrete screed, which complicates the possibility of repair. And, in addition, underfloor heating in this design will hide the space of the room, reducing the height of the ceilings.

Considering that the water type of the system is connected to the heating of the object, it is advisable to equip it in private housing when an individual project is being drawn up. And in the apartment it is quite possible to lay a more compact, lightweight, and also easy-to-install electric warm floor under the linoleum, and it is better to do this with your own hands in order to reduce costs.

The water type of construction has an important advantage - high inertia (slow heating / cooling), which does not allow the linoleum to overheat.

If you choose a film material, then in this case you can also increase the inertia. For this purpose, a warm floor is laid under linoleum on a wooden floor, for example, plywood sheets. We must not forget that the electrical analogue creates, albeit a minimal, but effective electromagnetic field.

Preparation of a concrete base for laying linoleum:

Before proceeding with the main work on the preparation of the base, it is necessary to free the room from all unnecessary things, remove the baseboards and old coatings. After that, if a screed was previously made on a concrete base, you should make sure of its reliability and make the necessary restoration. The resulting cracks, chips, delamination can be quickly repaired using putties with plasticizers.

It is more difficult to solve the issue if the concrete base does not have a screed and there are many irregularities on it. There is a need for a screed device, for which sand-cement or concrete mortars are traditionally used, but now it is much more convenient to do this using self-leveling mixtures. The advantage of these mixtures is their ability to create a perfectly flat plane and dry within a few days, while linoleum can be laid on a concrete screed no earlier than a month after it has completely dried. In order to get rid of possible dotted projections of small inclusions, the base is processed with coarse-grained sandpaper or a grinder.

In some cases, instead of repairing a concrete base, it is easier to lay on it sheet leveling materials such as chipboard or fibreboard, gypsum fiber sheets or plywood - this will not only level the floor, but also serve as additional insulation.

Practical advice

To improve the operating conditions of a film warm floor under linoleum, it is recommended to follow several rules.

Warm floor under linoleum

- Do not heat the material above + 26 ° C. As a result of prolonged heating to high temperatures, linoleum can exfoliate, change the original color in places of greatest heating, soften and significantly reduce the factory strength characteristics. Increased heating increases the amount of chemical compounds released into the air.

- When laying linoleum, do not use mastics to fix it. In addition to the fact that all mastics become additional sources of emission of harmful compounds, during uneven heating they can form swelling on the surface. It is very difficult to remove such defects later, and in many cases it is impossible. Linoleum simply spreads over the floor surface. If there are fears of movement, then it is possible to fix the coating with a stapler in several places, the staples are driven in inconspicuous places, the best option is under the floor plinths.

- Do not overlap thermal films. If the configuration of the room is very complex, then it is better to leave a small section of the floor unheated.

- The temperature in the room during the laying of linoleum should be at least + 18 ° С, otherwise the formation of hard-to-remove folds is possible.But you cannot spread it on a hot floor, after testing it must cool down to room temperature.

- It is not recommended to use this type of floor as the main heating system. The fact is that it is possible to heat the premises to comfortable temperatures when the floor is heated to t ° ≥ + 28 ° C, and this cannot be allowed in the case of using linoleum.

Adjust the operating modes only after carefully studying the instructions. The first few days of operation of the warm floor, it is advisable to check the reliability of functioning more often. It is recommended to check the floor temperature with an accurate household thermometer as a guarantee. If significant differences are found in the indicators, then it is necessary to make adjustments during the installation of the thermal control.

Finishing coating laying technology

It is important to comply with a number of laying requirements so that the material does not deform during operation.

Before starting work, linoleum must be rolled out and allowed to rest for 2-3 days in the conditions where it will be used. In accordance with the temperature and humidity conditions, the material shrinks slightly, which is normal.

After that, the covering is cut in accordance with the dimensions of the balcony. Take into account the presence of rounded corners, protruding parts of the walls.

Cut linoleum with a construction knife

When working with a concrete base, a special adhesive is used. It is selected in accordance with the microclimate of the room and the characteristics of the coating. For a frost-resistant material, an appropriate glue is needed. It is applied to the working base with a notched trowel or a wide brush, linoleum is laid and ironed with a rubber roller.

The covering is simply spread if there is a warm floor. Fix with baseboards around the perimeter of the room. The skirting boards should be installed from the far corner of the longest wall. Fastened with self-tapping screws with dowels.